To achieve yields near 100%, semiconductor manufacturers must master a procedure called yield learning. This consists of removing one source of faults after another until an overwhelming number of manufactured units work according to specification. In today’s fabs, better data collection, integration, and visibility are all needed to improve yield learning and accelerate ramp.

This blog illustrates the value of yield and defect management solutions capable of integrating with other fab systems to provide faster yield learning. It highlights Applied’s recently released yield and defect management solutions and includes two examples that show how these systems control Q-time and identify sources of defects using better visualization.

The Value of Collaboration

To help customers with their yield learning, the Automation Products Group at Applied Materials recently partnered with XDMTech Inc., a Taiwan-based company specializing in yield and defect management.

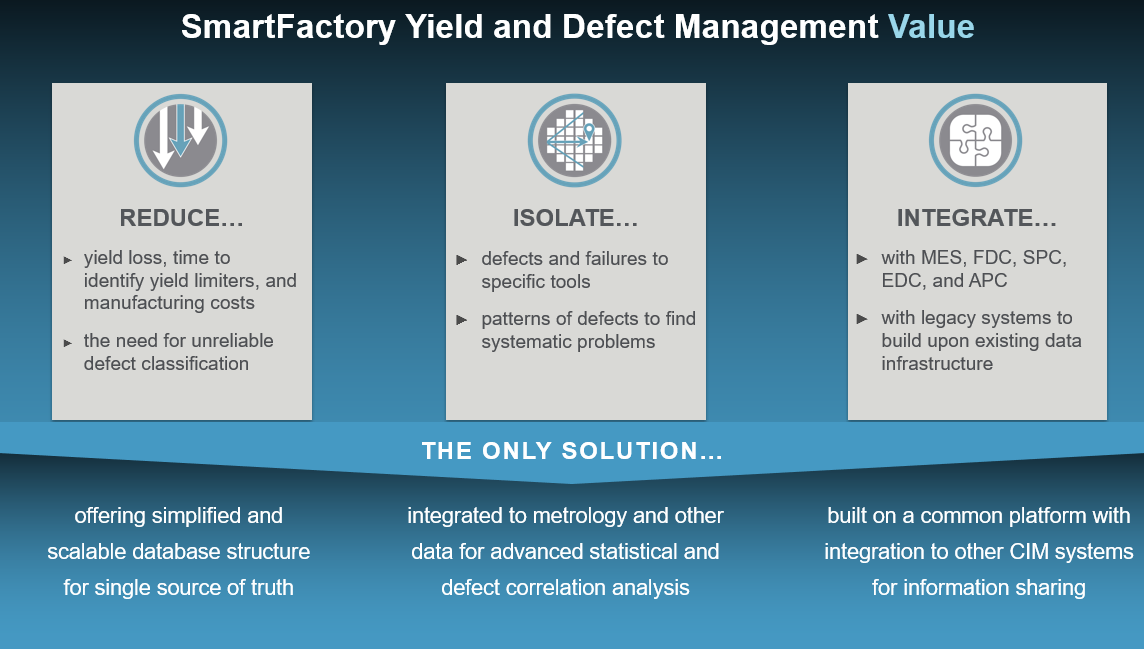

The results of this partnership are recently released SmartFactory Yield and Defect Management solutions built on the XDMTech Vidas and xDMS technologies. SmartFactory Yield Management is an integrated, fab-wide yield data management and analysis system. It helps engineers improve yield learning and accelerate yield ramp. The complementary product, SmartFactory Defect Management, reduces the need for unreliable manual defect classifications, and it also reduces yield loss, time to identify yield limiters, and manufacturing costs.

The availability of these solutions enhances Applied’s CIM portfolio and creates a one-stop shop to help manufacturers with their yield learning efforts.

What Makes These Solutions Different?

Key differentiators of the SmartFactory Yield and Defect Management include:

- Simplified Database. Yield and defect management are the only solutions offering a simplified and scalable database structure for single source of truth and faster root cause analysis. The result is improved profitability through increased product portfolios and cost reductions.

- Statistical Analysis Tools. Unlike many defect management solutions, which rely only on business intelligence (BI) tools, SmartFactory Defect Management provides additional statistical analysis tools and a workflow engine for automatically generating analysis reports.

- Better Integration. SmartFactory Yield Management is the only solution integrated to metrology and other data for advanced statistical and defect correlation analysis. It’s also the only process quality solution built on a common platform with integration to other quality systems, including MES, FDC, SPC, EDC, and APC. Such integration is critical because it enables information sharing across components, providing analysis of various data sources in a fab, as well as proven multi-fab data integration and traceability capability.

Example 1: The Value of Integration in Resolving Q-time Issues

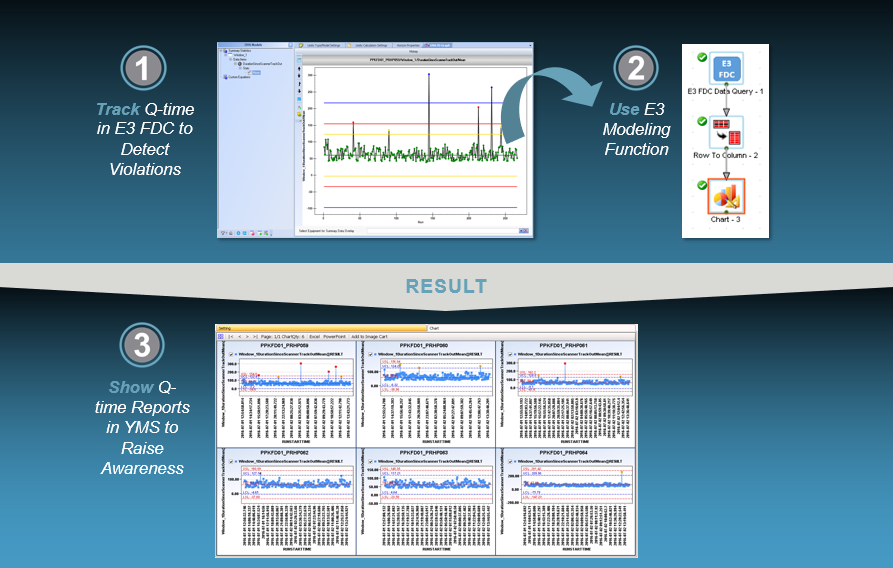

One of the key advantages of SmartFactory Yield Management is it enables information sharing across all process control elements. To illustrate, a large 300mm fab in Asia faced many yield challenges associated with its Q-time violations. Q-time refers to the defined limit on the total time between two or more consecutive steps. Wafers exceeding this time limit may be scrapped or result in potential yield loss.

To reduce the risk of scrapped wafers or lower yield, lots must spend less time in the loop than the Q-time limit. With this fab’s current in-house system, it was very difficult to integrate with SmartFactory Fault Detection to quickly access reports for showing Q-time violations. Furthermore, the fab had no automatic reporting tools or methods in place to control Q-time, resulting in slow response times and inaccuracies.

Applied Materials was able to resolve these challenges by integrating SmartFactory Yield Management and SmartFactory Fault Detection. This enabled the fab to set up alarms to notify engineers of any Q-time violations, as well as automatically generate hourly reports to clearly show violation trends in Yield Management (see Figure 2). By using SmartFactory Fault Detection modeling and yield management functions together, the fab was able to control and monitor wafer-level Q-time, resulting in faster yield learning.

Example 2: Identifying Defects with Better Visualization Tools

Wafer fabrication requires many tools and process steps, so conducting tool and robot induced defect analysis is time consuming. For manufacturers, it’s very difficult to determine the root cause of defects without adequate visualization and classifications tools.

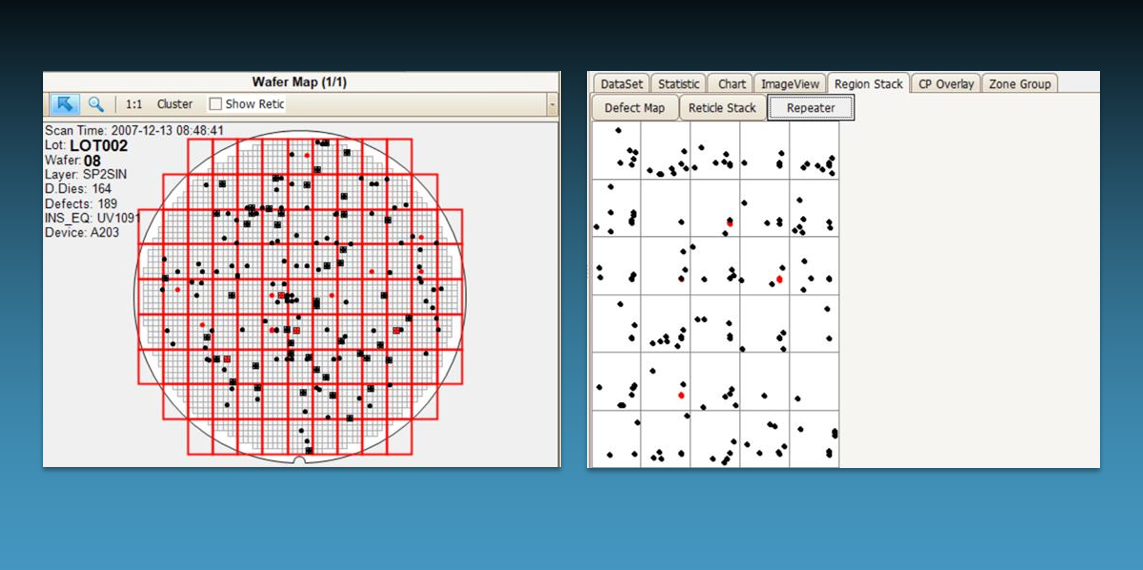

With typical defect management systems, manufacturers can only define wafer zones according to pre-defined zones, such as “upper” and “lower” or “center” and “edge.” However, with SmartFactory Defect Management, manufacturers can conduct contact pin analysis, which is enabled by importing equipment CAD drawings into the application’s library. This allows manufacturers to complete their analysis with the help of an overlay CAD drawing, an example of which is shown in Figure 3.

SmartFactory Defect Management tracks and classifies sources of defects using tools to help identify possible trends. Its geometric visualization superimposes geometric equipment components that may release particles on wafers.