For semiconductor fab managers who are considering artificial intelligence (AI) and machine learning (ML) technologies, here are some questions to consider: What’s the lifecycle of developing an AI/ML module for your specific problem? What’s an efficient way of implementing an AI/ML module with your current legacy system and production environments using SmartFactory productivity products, such as AutoSched®, Activity Manager® and APF Formatter? Are you aware of an integrated solution approach that covers the entire lifecycle of developing AI/ML modules?

Manufacturers relying on our SmartFactory Productivity AI/ML platform, which supports the entire AI/ML model development lifecycle are shortening development lead-time by more than 30%

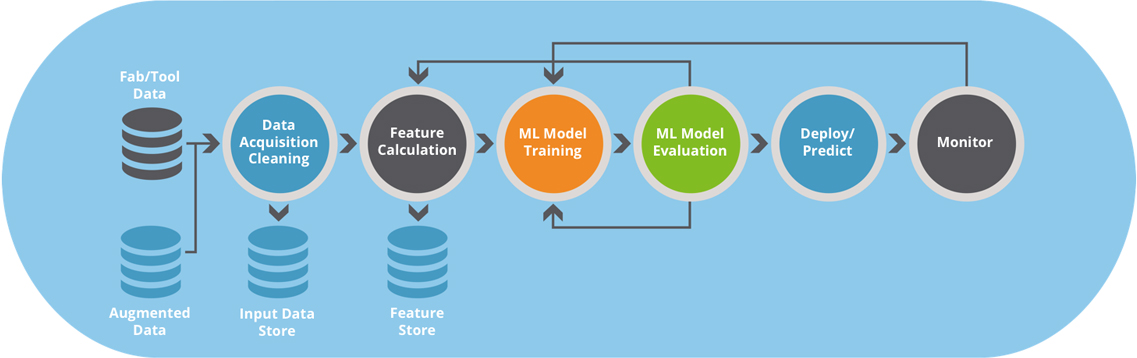

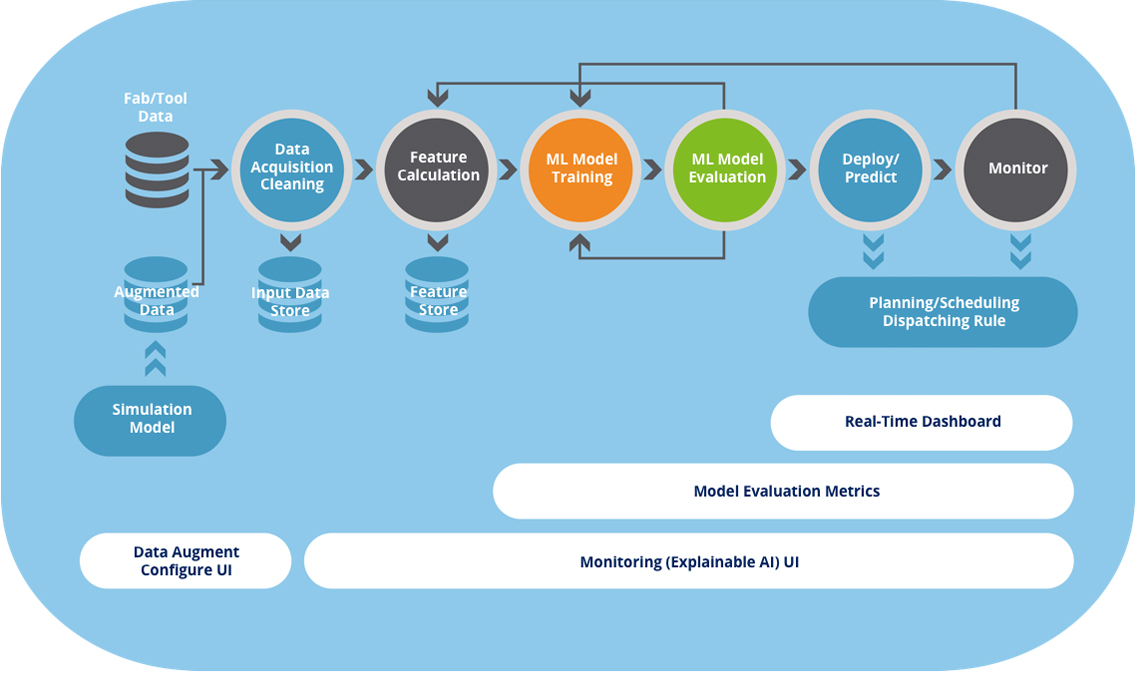

Standard Steps in AI/ML Module Development Lifecycle

The AI/ML module development lifecycle consists of four standard steps: preparing and acquiring data, defining and calculating features, training and evaluating the ML model, and deploying and monitoring the model (see Figure 1).

- Step 1. Data preparation and acquisition. If the historical fab or tool data is ready, then acquiring and cleaning data occurs first. If the historical data is not enough to represent future changes, then augmenting data is required.

- Step 2. Feature definition/calculation. After the fab or tool data is ready, the fab operation team should define key problem features to solve, including tool statistics and job attributes. After team defines the features, they are calculated automatically.

- Step 3. ML model training and evaluation. What’s the best ML algorithm for the problem? Lasso regression? Xgboost? The team defines the appropriate algorithm based on the type of problem. During this step, the team repeats training and evaluation as needed, and tunes features and parameters/hyper-parameters based on results.

- Step 4. Deployment and monitoring. During this final step, the model is deployed to production but note that this deployment does not impact the performance of the current production system. Deployment is easy and efficient. After the team implements the model, real-time monitoring highlights model performance and production impact.

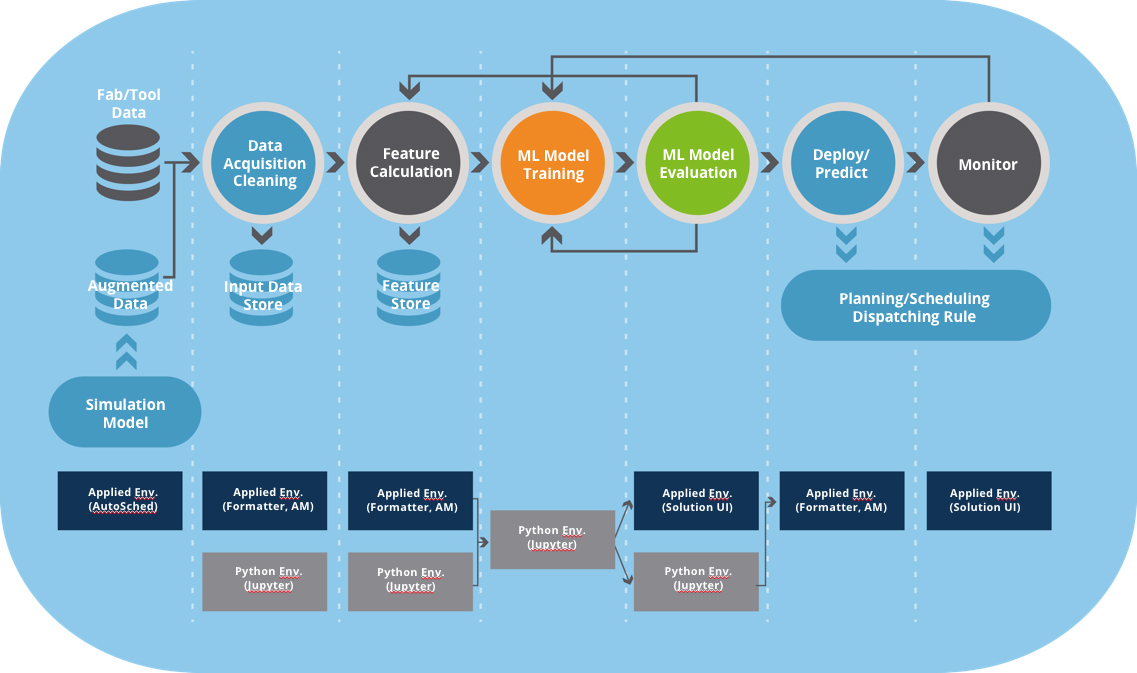

Fab manufacturers improve efficiency using SmartFactory Productivity Al/ML Platform

Fab manufacturers using our SmartFactory Productivity AI/ML Platform components, such as AutoSched, APF Formatter, Activity Manager, and Solution UI, can integrate these modules directly into their production environment and avoid the need to develop separate python programs typically required for each step in the AI/ML development lifecycle. Integrating these modules, enables manufacturers to reduce costs and avoid the need for additional development resources (see Figure 2).

- Step 1. When preparing and acquiring data: For fab managers who are required to augment data for the new fab or tool data, AutoSched offers a good simulation product to generate augmented data for new fab behavior or tool statistics.

- Step 2. When defining and calculating features: After defining a full set of features, feature calculation should be automatic. If new features are required, then adding new ones and modifying existing features should be easy in the current environment. Activity Manager performs this automation, and feature calculation is easily implemented using APF Formatter.

- Step 3. When performing ML model training and evaluation: During this step, the initial model training and evaluation will be done on the general python development environment. This platform will also provide ready-to-use ML models for solving common factory productivity and supply chain problems. These models serve as “baseline” models that manufacturers can freely modify and reuse as needed. Additionally, Solution UI provides various evaluation interfaces to speed up model training and evaluation.

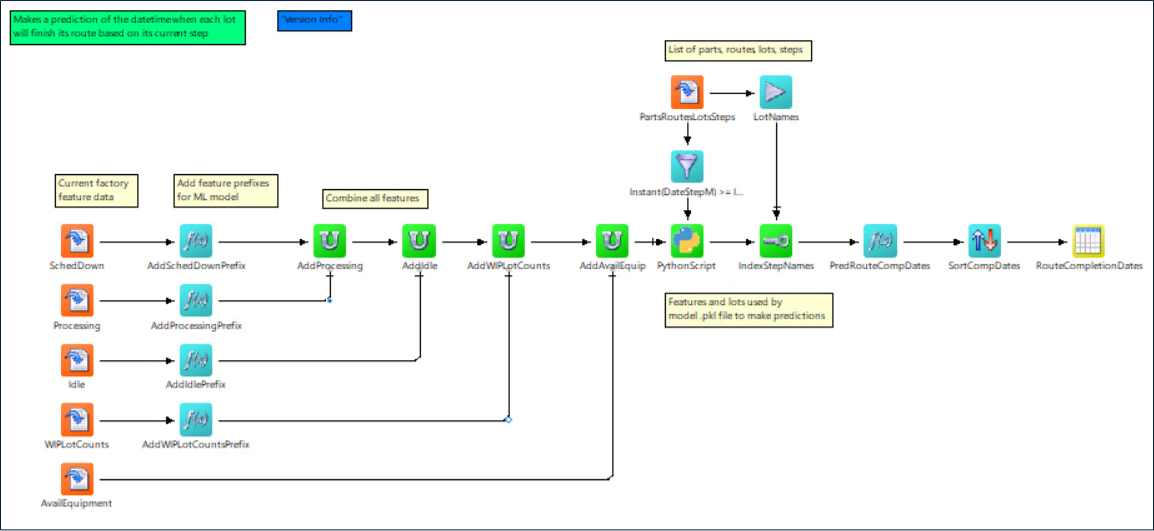

- Step 4. When deploying and monitoring the ML model: Deploying a ML model into production should not burden the current production system and is better off done in the familiar environment of current rule developers. If these developers use APF Formatter not only as their rule development tool, but also as their deployment tool (see Figure 3), then this is optimal. And rule developers can simply use the Python block to deploy an ML model to production—same as the current way. The Solution UI provides a dashboard and real time monitoring for model performance and fab impact monitoring.