Did you know that the number of alarms raised by various systems or devices can reach up to 1000 per second in high-volume manufacturing factories? In fact, managing numerous concurrent alarms or alerts, becomes a major distraction for operators, which means they can miss critical alarms that can cause scrapped wafers or excursions. When operators experience these issues, they become de-sensitized, getting overwhelmed with alarm spam. As a result, responses to alarms are delayed, leaving tools in a problematic state for extended periods of time, or misprocessed wafers continue to run without being inspected.

Handling hundreds and thousands of alarms per day is still a common operational challenge for many high-volume manufacturing factories. In fact, to handle the load, manufacturers must consistently manage and respond to large numbers of alarms in real-time. Relying on a solution to efficiently manage alarms in the factory to optimize operations means operators are empowered to focus on critical alarms that need immediate attention and filter out the less important alarms.

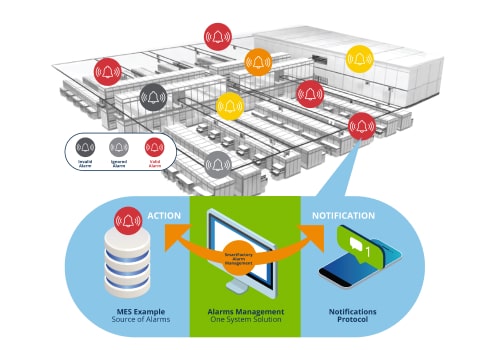

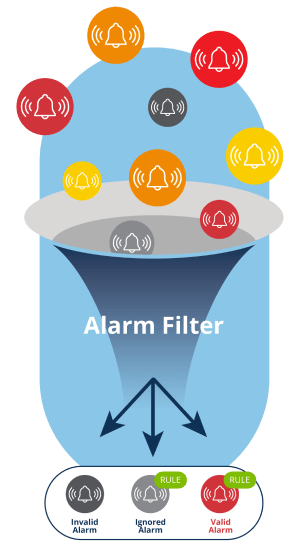

We’re launching SmartFactory Alarm Management, a new solution built to address these alarm management challenges in real-time. Fig 1 shows how filtering alarms improves productivity.Benefit Highlights

Excursion prevention to improve yield

Since alarms are filtered, operators can quickly identify the critical alerts, making it easier for them to address priority issues quickly and avoid misprocessing wafers.

Since alarms are filtered, operators can quickly identify the critical alerts, making it easier for them to address priority issues quickly and avoid misprocessing wafers.

Reduced tool downtime to increase tool utilization

Faster responses to targeted alarms enable technicians and engineers to take quicker and appropriate action and save tool time that otherwise would be lost.

Faster responses to targeted alarms enable technicians and engineers to take quicker and appropriate action and save tool time that otherwise would be lost.

Reduced cycle time to increase throughput

Reduced production noise and alarm data consolidation, enables users to troubleshoot production issues quickly. Resulting in labor productivity improvements and operations efficiency.

Reduced production noise and alarm data consolidation, enables users to troubleshoot production issues quickly. Resulting in labor productivity improvements and operations efficiency.

Manufacturers using SmartFactory Alarm Management see improvements in operations efficiency, throughput, and yield

Offering Highlights

- Centralize real-time alarm handling in one single location

- Streamline management of alarms from various systems through consistent procedures

- Apply alarm filtering hierarchy to choose the best alarm rules

- Apply alarm criticality hierarchy to take the best alarm actions

- Reduce production noise with a de-duplication algorithm

- Consolidate alarm data for fast troubleshooting and resolution

Ready to contact us to learn more about our SmartFactory Alarm Management?