Manufacturers are always interested in maximizing process tool availability and minimizing down-time. This is particularly the case in the semiconductor industry, where capital equipment costs are exceedingly high.

An often-overlooked component in maintenance downtime is the time it takes to re-qualify process tools following maintenance. Accelerating this post-maintenance qualification process can reduce overall maintenance downtime and improve process tool availability. SmartFactory 300works provides a systematic approach to automating the process.

Consider a simple example where an equipment engineer needs to run a monitor wafer to re-qualify a tool after preventive maintenance. This would ordinarily be a manual process during which the engineer looks to:

- Determine which qualification process flow is required

- Ensure the required wafers are available and ready for use

- Retrieve the required wafers from storage

- Process the monitor wafer(s)

- Evaluate the results and decide the disposition of the process tool

This is conceptually simple, but it’s a time-consuming, manual process – particularly when something unexpected occurs, such as discovering that the required wafers aren’t available or aren’t ready to use. It becomes a big drain on factory efficiency.

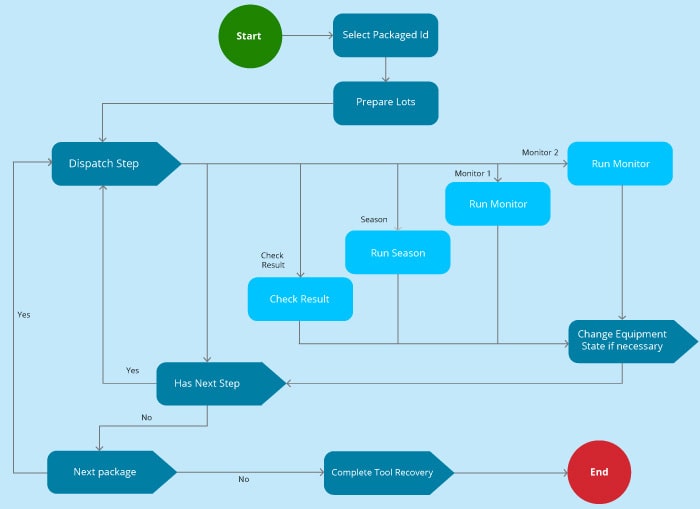

Figure 1 shows how a monitor wafer process flow associated with preventive maintenance might be implemented within the automated tool recovery package.

This is how 300works automated tool recovery package improves the process by:- Locating the proper monitor wafers and ensuring they’re properly prepared for use

- Downloading the process recipe to the process tool and initiating processing

- Uploading processing results

- Automating the disposition decision and returning the monitor wafers to storage ready to be used again

The overall impact of automating post-maintenance re-qualifications can be significant – particularly for bottleneck tools.

Our 300works automated tool recovery workflow ensures the proper re-qualification process flow and monitor wafers are used, and that re-qualification disposition occurs in a consistent manner. It also accelerates the re-qualification process, reducing tool down-time and gets tools back up and running in production quickly.

Interested in learning more? Reach out here for more information!