This 2-part blog series was inspired by a live presentation delivered at The Battery Show North America on October 8, 2025

Live Presentation

Agnes Sowa

India can skip over the decades and billions of dollars that its peers invested to develop the cutting-edge smart manufacturing technologies that are best practice today. In doing so, new semiconductor factories in India, both wafer fab and packaging, can enjoy improved time to market while optimizing yield, cost, and output. In short, India’s semiconductor industry can benefit from the collective work, investment and learnings of the rest of the world to build the smartest, most productive factories, building the highest quality products at the lowest cost. They can shift the S-curve, as we say, to produce more good die at every stage of the factory lifecycle.

In this first blog, we’ll look at the origins of manufacturing and what it means to make it “smart.”

Background

Making maintenance objectives quality objectives

Quality teams concentrate on yields, which translate directly into free cash flow for the business. This makes them much more tightly connected to company profitability than the maintenance team, whose focus is typically on asset uptime and availability (throughput)—but if they are doing their jobs right, they are removed from the main daily operations. Having a competitive battery gigafactory means you are getting maximum overall equipment effectiveness (OEE)—to oversimplify, running highest throughput at highest yield.

By reframing maintenance objectives as quality objectives—aiming to prevent defects tied to equipment downtime—you’re effectively aligning your maintenance operations with the quality team that holds the key priorities, resources, and strong links to business goals. In practice, process engineers review statistical process control (SPC) data, leverage fault detection (FD) to find root causes (the why in a process 8D), and build process Failure Mode Effects Analyses (FMEAs), all of which help keep the maintenance schedule alive as an active tool to reduce process failures. Whenever a new failure mode or lesson arises, you have another team, the quality team, supporting your work.

Use case

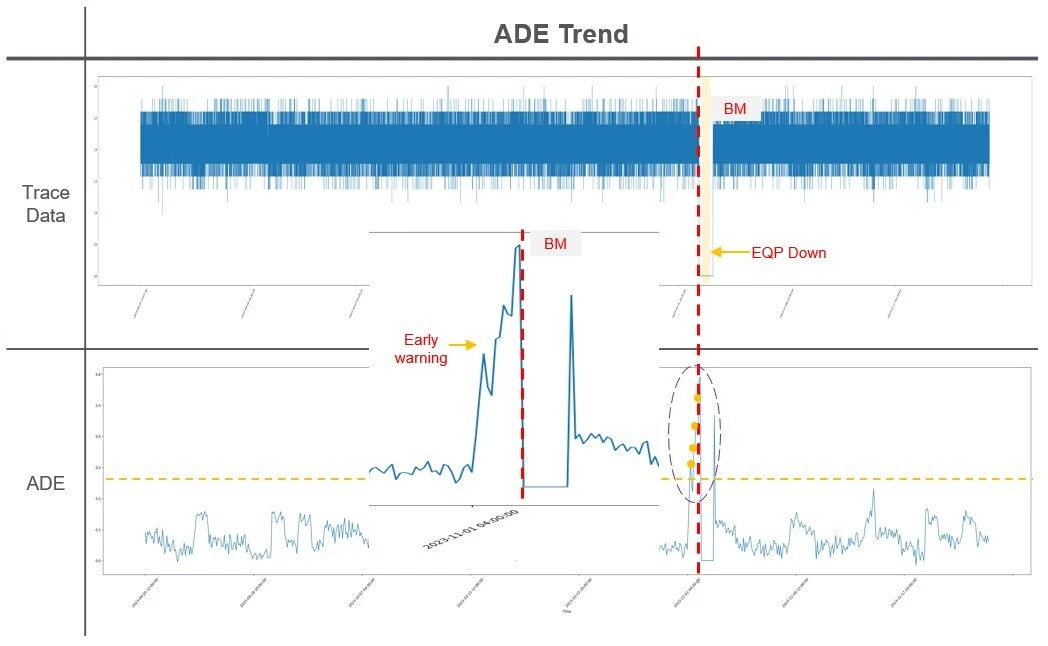

With this approach, it took just three months to install ADE, customize it, choose the right algorithms, and run it in live production—realizing enough value that the customer expanded it across their plant and other global sites.

Our main hypothesis was cutting maintenance events and downtime, which we did, but we also shifted unplanned maintenance toward scheduled, planned interventions—cutting scrap and resulting in a recalculated operational savings in the millions of dollars.

Considering each phase and the resources needed for this type of implementation, there are some factors to note: data resources and careful algorithm selection is important and working with the process engineers is critical to success. The goal is to link your maintenance, trace, test, alignment, and fault detection data together.

Picking and prioritizing use cases that fit the business model is crucial. Sometimes, a preventive maintenance work instruction lets you skip steps, but the real gain from doing so can be small (you’ve already got the cover open and a tech onsite, so there’s minimal extra time). This is where your maintenance team’s expertise guides decision-making based on ROI and cost-benefit, and that’s how you build the model.

With ADE, we believe we’ve made automating maintenance implementation simpler and effectively automated the scheduling for cell manufacturing.