For semiconductor frontend manufacturers, having a goal of achieving full automation is a critical factor for leading and supporting a successful fab with required automation capabilities.

However, the path to reach this goal varies and depends on numerous factors. Several risks prevail in this process, depending on customer management and whether the right partnerships are developed for journeying on the path together.

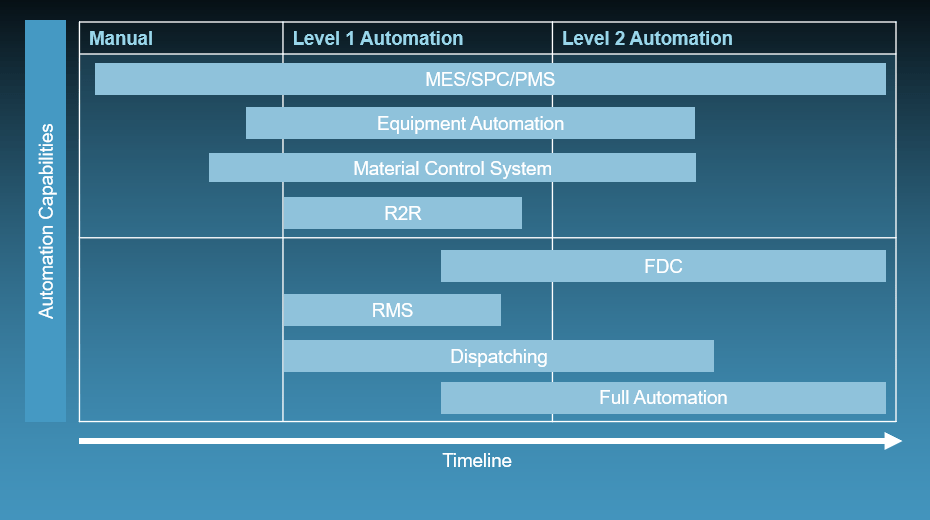

When customers successfully achieve their first MES deployment with basic automation and can run wafer processes, then it’s time to establish a vision focused on increasing factory automation capabilities with the goal of closing in on full automation in a timely manner.

What Is Full Automation?

Full automation, also known as full-auto or lights out manufacturing, enables factories to process products automatically with minimum human interaction1. Full automation enables fabs to optimally use data and computer systems to enhance productivity.

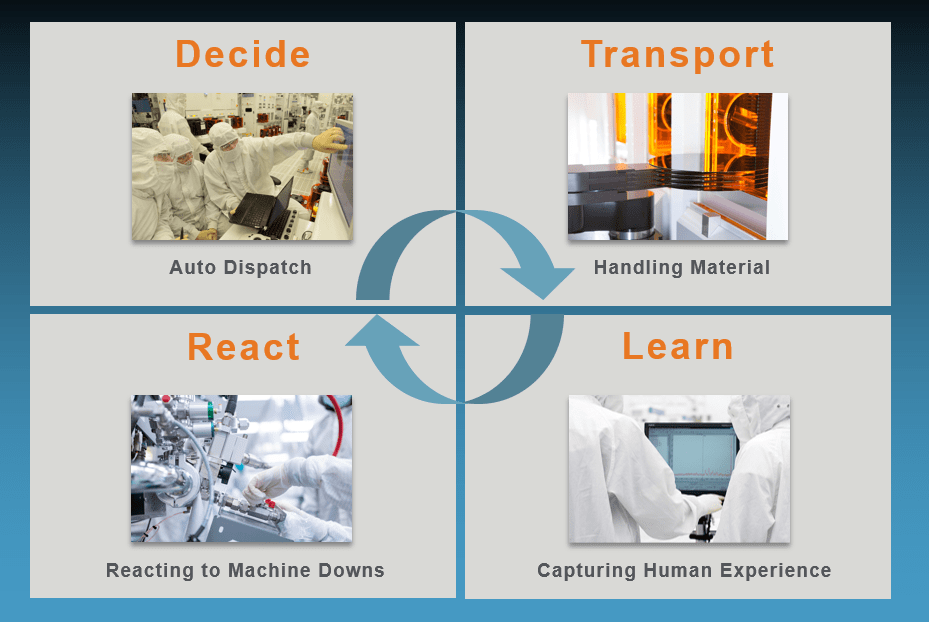

The following diagram illustrates the concept of full automation, showing the flow or relationship among making decisions, transporting material, learning, and reacting to exceptions.

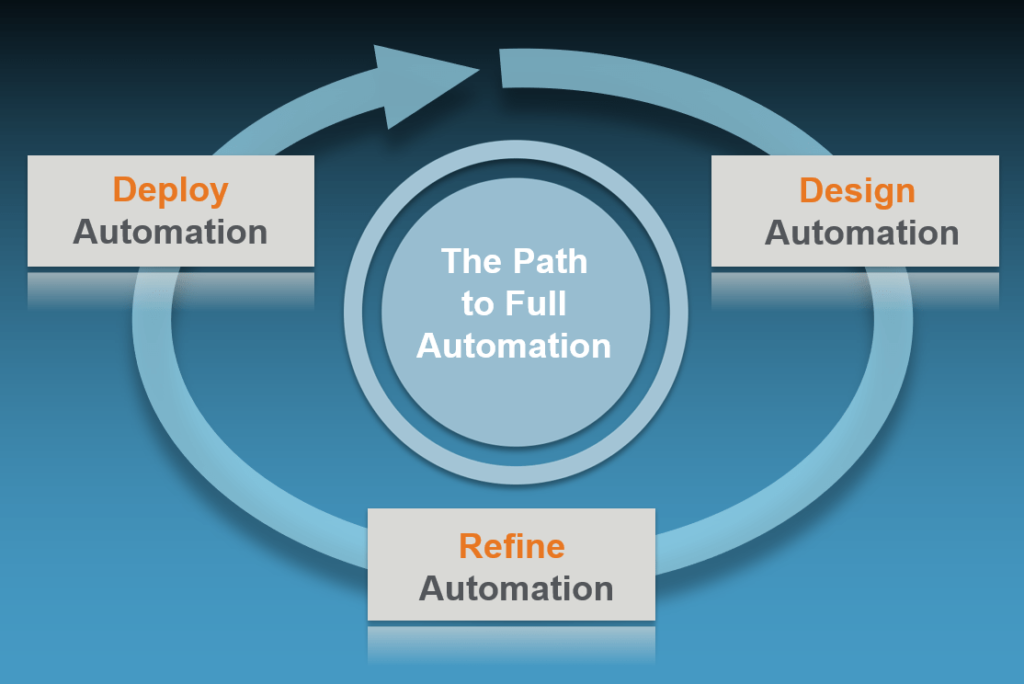

- Design automation scenarios. Factories have different needs and conditions that they must manage, such as factory space constraints and tools with limited online capabilities. Such conditions require that factories carefully consider and design automation scenarios, so they work with multiple applications like dispatching, run-to-run control, fault detection and classification, alarm management, recipe management, and others depending on factory automation scope.

- Refine operation capabilities. The timeline for implementing full automation involves refining MES execution scenarios based on processes and equipment that are continuously being added in the factory. Factories will continuously change to increase production output, so it’s inevitable to change manufacturing scenarios, including equipment form factors, integration with the automated material handling system, and so forth. Change is constant in a fab, particularly after deployment because customers are continuously looking to improve operational efficiency.

- Deploy automated capabilities. Following design and refinement, factories can start deploying automation capabilities with full automation scenarios to implement no or minimum human intervention.

Use Case: Common Challenges with Advanced Automation

- Building a company-wide view of full automation

- Lacking or not having enough automation knowledge, particularly with integration

- No expertise on how to improve

- Limited view on how to prioritize automation tasks

Partnering for Advanced Automation

- Complete full-auto readiness in 6–9 months

- Production ramp from basic automation to semi automation to increase yield and output

- On time readiness for full automation

Deploying an MES, together with automation applications following a systematic and experienced approach, is provided through Applied’s proven solution. This solution is built on expertise gained through many deployments over the years. Applied SmartFactory MES 300works® is market-proven for achieving fast MES deployment in 90 days. The solution enables customers to execute in their factory with fully automated capabilities within a year.

REFERENCES

[1] Krishnaswamy, S., Hanny, D., & Napiah, J. (n.d.). Challenges and strategies to achieve full automation in semiconductor assembly and test. Semi.org. Retrieved June 29, 2022, from https://www.semi.org/en/about/AMAT

Ready to contact us to learn more about our MES deployment methodology?