In the semiconductor industry, timely delivery of reticles is crucial for wafer manufacturing. Traditionally, the relationship between a wafer fab and its photomask vendor is driven by purchasing departments as a customer-supplier relationship, focusing primarily on pricing and on-time delivery per a pre-defined, contractual lead-time. However, this often leads to misalignment between the wafer fab’s needs and the contractual obligations of the mask shop, resulting in reticle delivery later than the fab’s need and costly premiums for expedited shipping.

Collaboration

A closer collaboration between wafer fab and mask shop can significantly improve reticle delivery to meet the fab’s wafer schedule without expedited shipping or price premiums. This approach is particularly beneficial for full reticle sets that support the manufacture of new products. The key to this collaboration is a shared understanding of the date reticles are needed in manufacturing (the “need date”) to meet the schedule of the lead lot, which is the first lot for the wafer fab’s new product.

Based on their experience with similar reticles, the customer’s reticle design team likely has a good idea of how long it will take to manufacture each reticle needed for the new product. They also know they must complete their internal design process for each reticle in time to allow the mask shop sufficient time to build and deliver the reticle to the wafer fab before the lead lot arrives at the process step in which it is used. The design team can predict their deadline, then, by working back from the expected wafer schedule created by their new product planning team.

The mask shop’s requirements

From the mask shop’s perspective, three critical dates must be known in advance for each reticle in the new product’s process flow. The first of these is the expected “tapeout” date – the date the reticle order and its accompanying design data will be received from the customer. The second and third critical dates are the wafer fab’s need date and the time required to ship the finished reticle to the wafer fab.

Given these dates, the mask shop can determine the lead time available to manufacture the reticle and a.) mobilize the appropriate resources to ensure they’re able to manufacture and ship the reticle to meet the wafer fab’s need date, or b.) push back well in advance if the lead time provided by the customer is inadequate. Assuming the wafer processing schedule is fixed, increasing the lead time would require an earlier tapeout date.

This shared understanding – created well before the first reticle for the new product tapes out – requires a lot of coordinated planning. It helps both the mask shop and the wafer fab understand the timing, anticipate the needs, mobilize the necessary resources, and proactively adjust to schedule changes to ensure the wafer fab is able to meet their product development commitments.

A novel approach?

But why is this a novel approach? One might expect this level of coordination to be standard practice to ensure the wafer fab gets what they need when they need it, just as they do with industrial chemicals, spare parts, cleanroom supplies, or any number of other manufacturing needs. It’s almost inconceivable that factory operations would be delayed or otherwise impacted because one of the fab’s suppliers didn’t deliver on time.

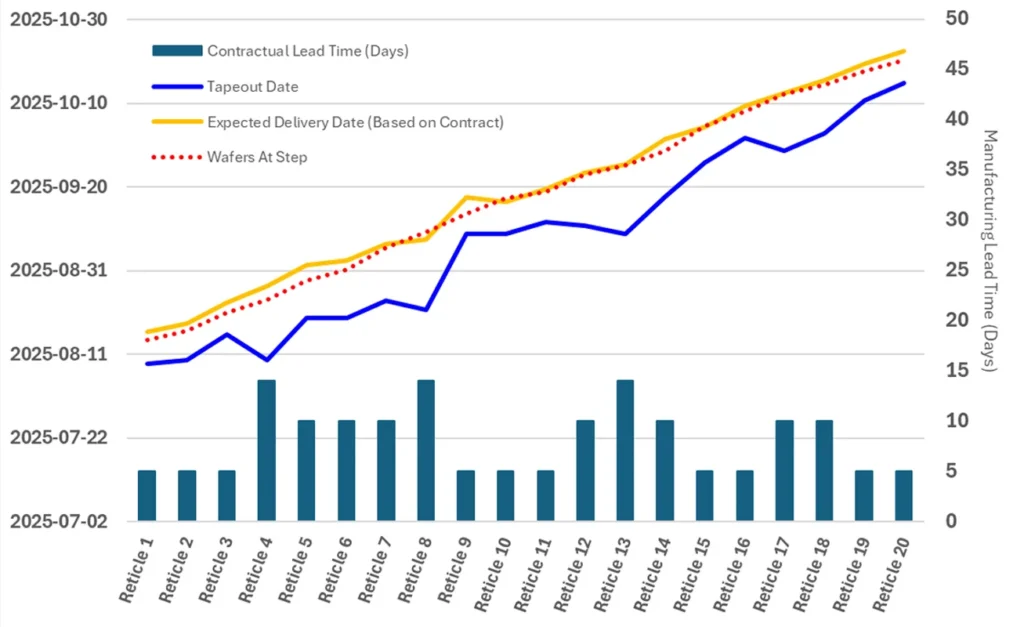

It’s the uniqueness of reticles that drives this paradox. There is no bulk supply that can be monitored and resupplied before it’s exhausted. There also isn’t a reserve inventory to draw upon when stocks get low. Each reticle is unique, ordered only when needed, and built to specification. As noted previously, the relationship between a wafer fab and its photomask vendor is driven by the fab’s purchasing team as a customer-supplier relationship, focusing primarily on pricing and on-time delivery per a pre-defined contract. This contractual arrangement does not – and cannot – take wafer fab need date into account.

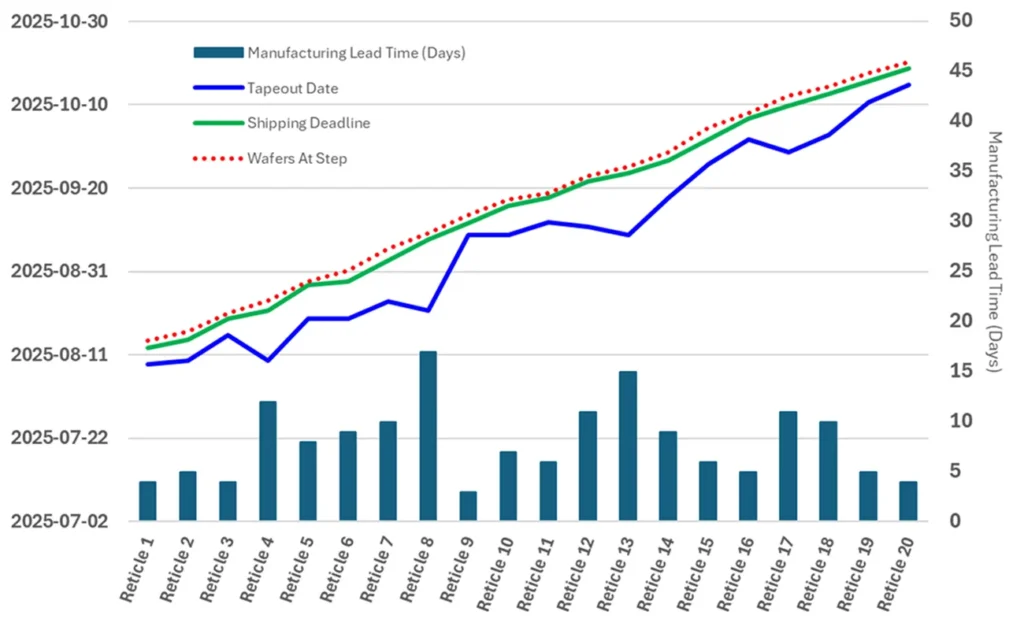

However, this inability to consider the wafer fab’s timing needs often results in delays that impact the wafer fab’s new product commitments. Consider the chart shown in Figure 1, where there is coordination between the wafer fab and mask shop. In this case, reticles are consistently delivered to the wafer fab on time before the need date.

The cost of inflexibility

Aligning reticle delivery with wafer manufacturing through a collaborative approach can significantly improve on-time delivery, reduce costs, and enhance performance of both the mask shop and the wafer fab.

Tracking reticle manufacturing progress against a coordinated schedule allows the mask shop to allocate the resources needed to ensure on-time delivery and helps proactively identify potential problems along the way.

MES as the coordinator

A Manufacturing Execution System (MES) plays a critical role in furthering a mask shop’s on-time delivery goals. By integrating MES planning and scheduling information, real-time data can provide insights into production status, equipment availability, and process performance. This enables the mask shop to make informed decisions, quickly address issues, and optimize resource allocation.

An MES can also facilitate communication and coordination between the mask shop and wafer fab, ensuring that any changes in the wafer fab’s schedule are promptly reflected in the mask shop’s production plan. This dynamic adjustment capability helps maintain alignment with the wafer fab’s needs and improves the reliability of reticle delivery.