The problem: alarm overload and its consequences

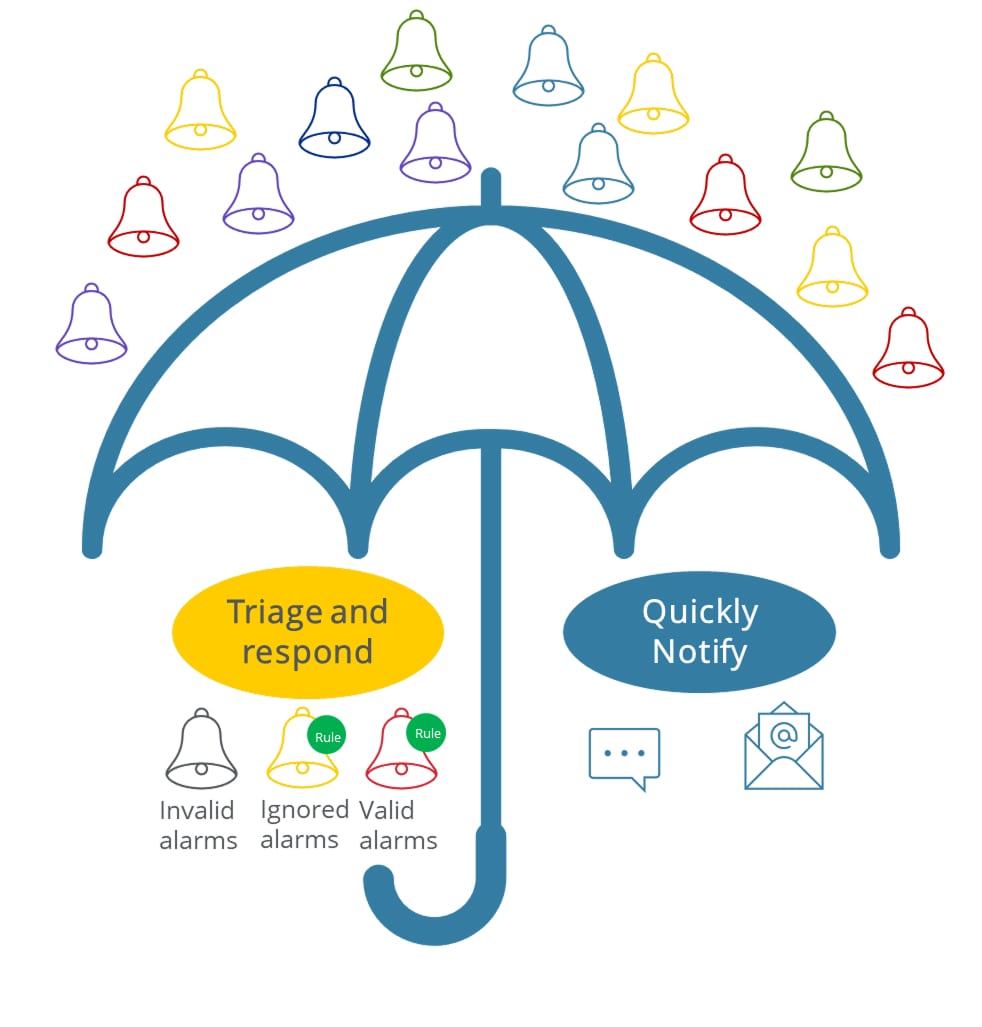

Semiconductor fabs are complex ecosystems. A single process deviation can trigger a cascade of alarms across multiple systems. Operators are often inundated with notifications—many of them false, redundant, or low-priority (see Figure 1). In fact, a study at STMicroelectronics revealed that more than 95% of alarms were low-priority, and only about 4% of alarms triggered any action [Al-kharaz et al., 2019]1. Worse, a small subset of alarms (just 100 out of more than 5,000) accounted for 70% of all alarm activity.

This “alarm noise” leads to:

- Delayed responses to critical issues.

- Operator desensitization, increasing the risk of missed alarms.

- Reduced productivity and increased scrap rates.

The research: data-driven insights into alarm performance

- Alarm floods—bursts of alarms in short timeframes—are often caused by chattering or repeating alarms and can obscure critical issues.

- Nuisance alarms (e.g., stale or standing alarms) contribute significantly to operator overload and should be reclassified or removed.

- Machine learning models can predict product scrap based on alarm patterns, achieving up to 75% accuracy (Al-kharaz et al., 2021)2. This opens the door to predictive quality control using alarm data.

The solution: SmartFactory Alarm Management

SmartFactory Alarm Management addresses these challenges head-on. It offers a centralized, automated, and integrated approach to alarm handling:

- Automated filtering and prioritization: Only meaningful alarms are forwarded, with duplicates and false alarms suppressed.

- Configurable notifications: Alerts are sent only to relevant staff, via email or SMS, with escalation paths if unacknowledged.

- Action automation: Alarms can trigger predefined actions like putting a lot on hold or logging a tool down across MES, equipment automation, and other systems.

- Comprehensive dashboarding: A real-time, factory-wide view of active alarms, plus historical analysis for root cause investigation.

The payoff: quality, efficiency, and peace of mind

By integrating alarm management into the broader SmartFactory ecosystem, manufacturers can:

- Reduce downtime by accelerating root cause analysis.

- Improve yield by catching quality-impacting issues earlier.

- Empower operators with actionable, relevant alerts.

- Streamline compliance with ISA and EEMUA standards.

Use case example

The SmartFactory Alarm Management 3.4.0 release included the integration of SmartFactory Knowledge Advisor (KA), which supports both containment actions (e.g., stopping a tool to prevent further issues) and corrective actions (e.g., steps to fix the underlying problem and return the tool to production). The integration of KA into the Alarm Management Solution (AMS) provides structured workflows for resolving alarms; Alarm Management identifies alarms from various tools and systems, and KA offers detailed action plans to address them. This improves efficiency of alarm management workflows, ensuring that alarms are not only identified, but also resolved promptly and effectively.

So how does it work? AMS identifies critical alarms, contains the event, and notifies users, but it does not provide steps for resolution. KA fills this gap by offering action plans that guide users through the resolution process, ensuring that alarms are addressed systematically. The application can support both automated and manual corrective actions. For example, an alarm can trigger an automated response to stop a tool, or it can generate a manual action plan for a user to follow. This streamlines the user experience by consolidating alarm management and resolution for E2E containment and correction and improves workflow efficiency.

Conclusion

References

[1] Al-Kharaz et al., 2019 – Evaluation of Alarm System Performance and Management in Semiconductor Manufacturing. 6th International Conference on Control, Decision and Information Technologies (CoDIT’19).