Leading the way to higher yields, quality improvements, time-to-market acceleration

This paradigm shift has transformed production processes. The urgency to optimize productivity and increase the demand for zero defects manufacturing is enabling factory innovators to achieve higher yields, significantly improve production quality, and increase time-to-market.

Our Applied SmartFactory team of automation technology experts continues to partner with leading semiconductor manufacturers around the world to help enable smart and reliable factory automation. Our customers rely on our team to figure out the best way to meet business goals and move toward full automation.SmartFactory Pillars Leading to Full Factory Automation

- Decision Making: Automation of complex decisions in the fab. These include operational decisions such as what to run next and when to run it. There is a high level of complexity in semiconductor fabs with vast run requirements for each step in the process.

- Transport: Automation manages the movement of materials within the fabrication facility. This includes transporting wafers between processing steps, storing them in clean environments, and ensuring timely delivery to various workstations.

- Exception Handling: Automated reaction to unexpected events in the factory and resolution of those events. This replaces labor intensive manual intervention for factory floor exceptions and limits delays to resolve these issues.

- Learning: Automation in the semiconductor industry isn’t limited to physical tasks. Data analytics and artificial intelligence are employed to monitor equipment performance, predict maintenance needs, and optimize production processes in real-time, minimizing downtime and improving efficiency.

There are several benefits to achieving full factory automation. Among these, manufacturers can realize enhanced efficiency by minimizing human errors, reducing cycle times, and increasing throughput. Automation enables round-the-clock production without compromising quality. There are also benefits in consistency and quality. Automated processes deliver consistent results, leading to fewer defects and higher-quality products. This is crucial in an industry where even a minuscule flaw can render a chip useless. As the demand for semiconductor products continues to grow, automation also allows manufacturers to easily scale up production without significant adjustments to their infrastructure. Another important benefit is in the long-term costs. While initial setup costs can be significant, automation leads to long-term cost savings through reduced labor expenses, improved yield rates, and efficient resource utilization.

Overcoming challenges to deployment

Despite its advantages, the implementation of factory automation in the semiconductor industry comes with challenges. Integrating diverse technologies, preparing the factory for automation, staffing the appropriate personnel, hardware/software purchasing, and configuration can all be significant roadblocks to overcome. Overcoming these challenges can be daunting, even discouraging some sites from adopting higher levels of automation. The challenges of smart manufacturing aren’t insurmountable, however, and can be overcome if manufacturers have a clear vision and pathway to meet timelines and goals.

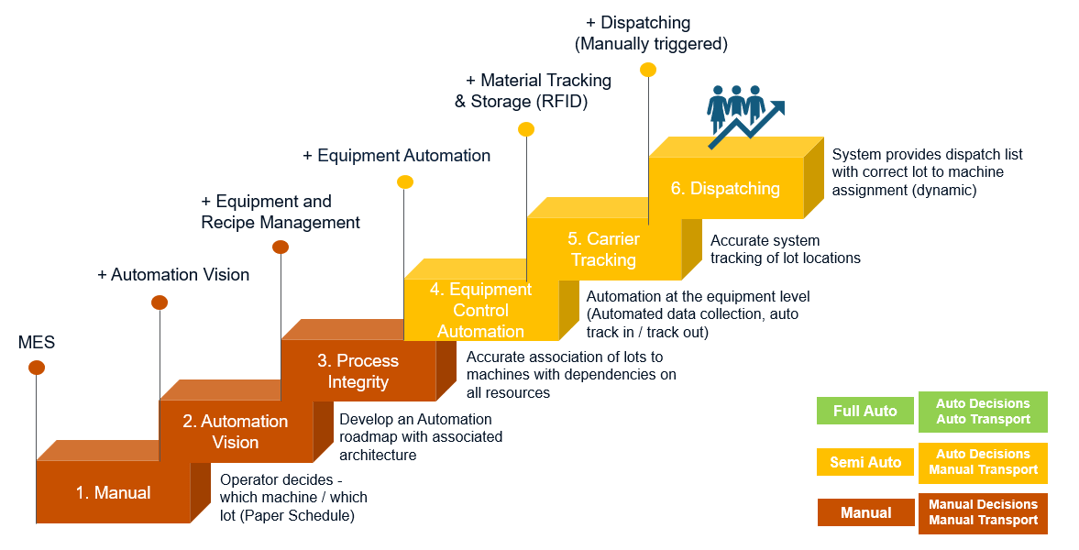

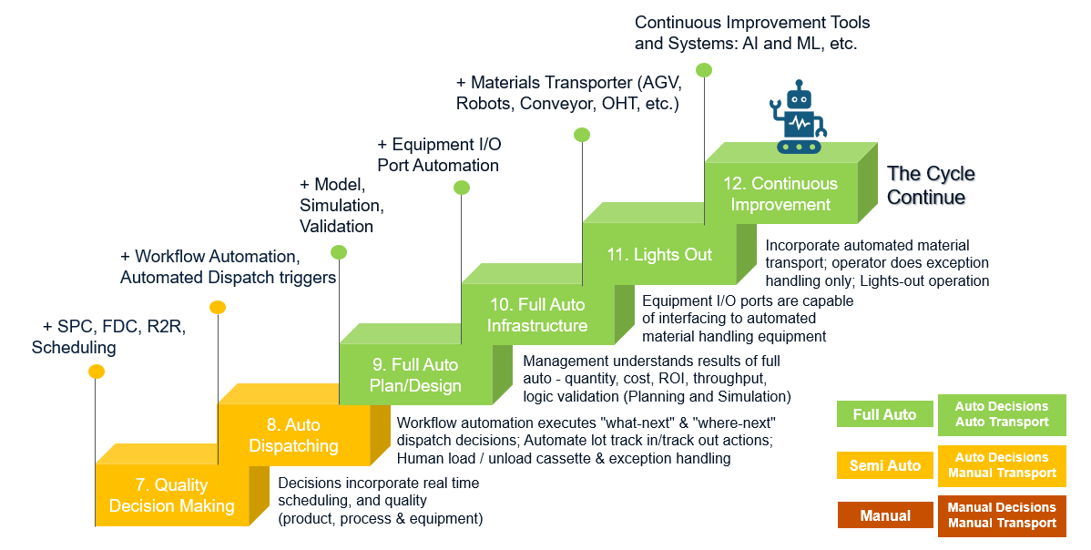

Working with customers, we have found it is easier for manufacturers to execute their full automation plans once they can define each step that needs to be achieved to reach their goal. First, organizations need to define where they are on their automation journey, then establish where they want to be, and finally identify the steps required to get there.

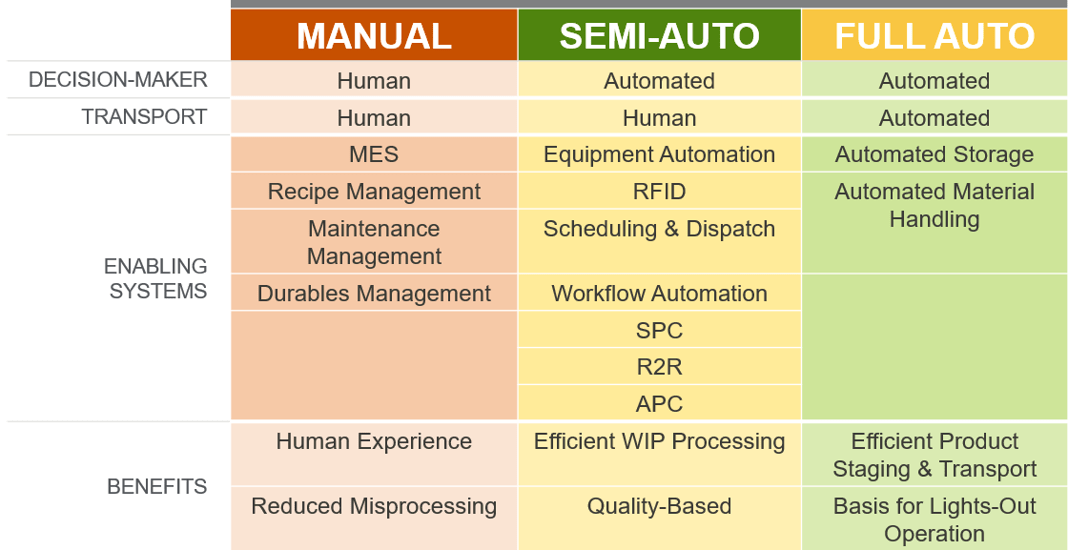

In helping them define where they are, we classify manufacturing organizations into three distinct categories: Manual, Semi-Auto, and Full Auto factories. Each category represents the level of factory automation deployed. Figure 1 shows the levels of factory automation.

Future outlook

Factory automation is reshaping the semiconductor industry, enabling manufacturers to meet the growing demand for implementing advanced electronics. By harnessing the power of robotics, AI, and data analytics, automation has elevated efficiency, quality, and scalability to unprecedented levels. As technology continues to evolve, the marriage of automation and semiconductor production improvements promises to drive innovation, shaping the future of smart manufacturing.

Learn more about the move to full automation: https://appliedsmartfactory.com/semiconductor-blog/move-to-full-automation/Improving yield, quality and time-to-market

This paradigm shift has transformed production processes. The urgency to optimize productivity and increase the demand for zero defects manufacturing is enabling factory innovators to achieve higher yields, significantly improve production quality, and increase time-to-market.

Our Applied SmartFactory team of automation technology experts continues to partner with leading semiconductor manufacturers around the world to help enable smart and reliable factory automation. Our customers rely on our team to figure out the best way to meet business goals and move toward full automation.

SmartFactory Pillars

- Decision Making: Automation of complex decisions in the fab. These include operational decisions such as what to run next and when to run it. There is a high level of complexity in semiconductor fabs with vast run requirements for each step in the process.

- Transport: Automation manages the movement of materials within the fabrication facility. This includes transporting wafers between processing steps, storing them in clean environments, and ensuring timely delivery to various workstations.

- Exception Handling: Automated reaction to unexpected events in the factory and resolution of those events. This replaces labor intensive manual intervention for factory floor exceptions and limits delays to resolve these issues.

- Learning:Automation in the semiconductor industry isn’t limited to physical tasks. Data analytics and artificial intelligence are employed to monitor equipment performance, predict maintenance needs, and optimize production processes in real-time, minimizing downtime and improving efficiency.

Benefits of Full Automation

There are several benefits to achieving full factory automation. Among these, manufacturers can realize enhanced efficiency by minimizing human errors, reducing cycle times, and increasing throughput. Automation enables round-the-clock production without compromising quality. There are also benefits in consistency and quality. Automated processes deliver consistent results, leading to fewer defects and higher-quality products. This is crucial in an industry where even a minuscule flaw can render a chip useless. As the demand for semiconductor products continues to grow, automation also allows manufacturers to easily scale up production without significant adjustments to their infrastructure. Another important benefit is in the long-term costs. While initial setup costs can be significant, automation leads to long-term cost savings through reduced labor expenses, improved yield rates, and efficient resource utilization.

Overcoming challenges to deployment

Despite its advantages, the implementation of factory automation in the semiconductor industry comes with challenges. Integrating diverse technologies, preparing the factory for automation, staffing the appropriate personnel, hardware/software purchasing, and configuration can all be significant roadblocks to overcome. Overcoming these challenges can be daunting, even discouraging some sites from adopting higher levels of automation. The challenges of smart manufacturing aren’t insurmountable, however, and can be overcome if manufacturers have a clear vision and pathway to meet timelines and goals.

Working with customers, we have found it is easier for manufacturers to execute their full automation plans once they can define each step that needs to be achieved to reach their goal. First, organizations need to define where they are on their automation journey, then establish where they want to be, and finally identify the steps required to get there.

In helping them define where they are, we classify manufacturing organizations into three distinct categories: Manual, Semi-Auto, and Full Auto factories. Each category represents the level of factory automation deployed. Figure 1 shows the levels of factory automation.

Future outlook

Factory automation is reshaping the semiconductor industry, enabling manufacturers to meet the growing demand for implementing advanced electronics. By harnessing the power of robotics, AI, and data analytics, automation has elevated efficiency, quality, and scalability to unprecedented levels. As technology continues to evolve, the marriage of automation and semiconductor production improvements promises to drive innovation, shaping the future of smart manufacturing.

Learn more about the move to full automation: https://appliedsmartfactory.com/semiconductor-blog/move-to-full-automation/

FAQs

How does advanced automation benefit semiconductor manufacturers?

Advanced automation helps semiconductor manufacturers achieve higher yields, improve production quality, and accelerate time-to-market by optimizing productivity and reducing defects.

What are the key pillars of SmartFactory leading to full factory automation?

The pillars include Decision Making (automating complex decisions), Transport (managing material movement), Exception Handling (automating reactions to unexpected events), and Learning (utilizing data analytics and AI for real-time optimization).