Scheduling: Lot Assignment

Dispatching: Lot Sequence

Misconceptions

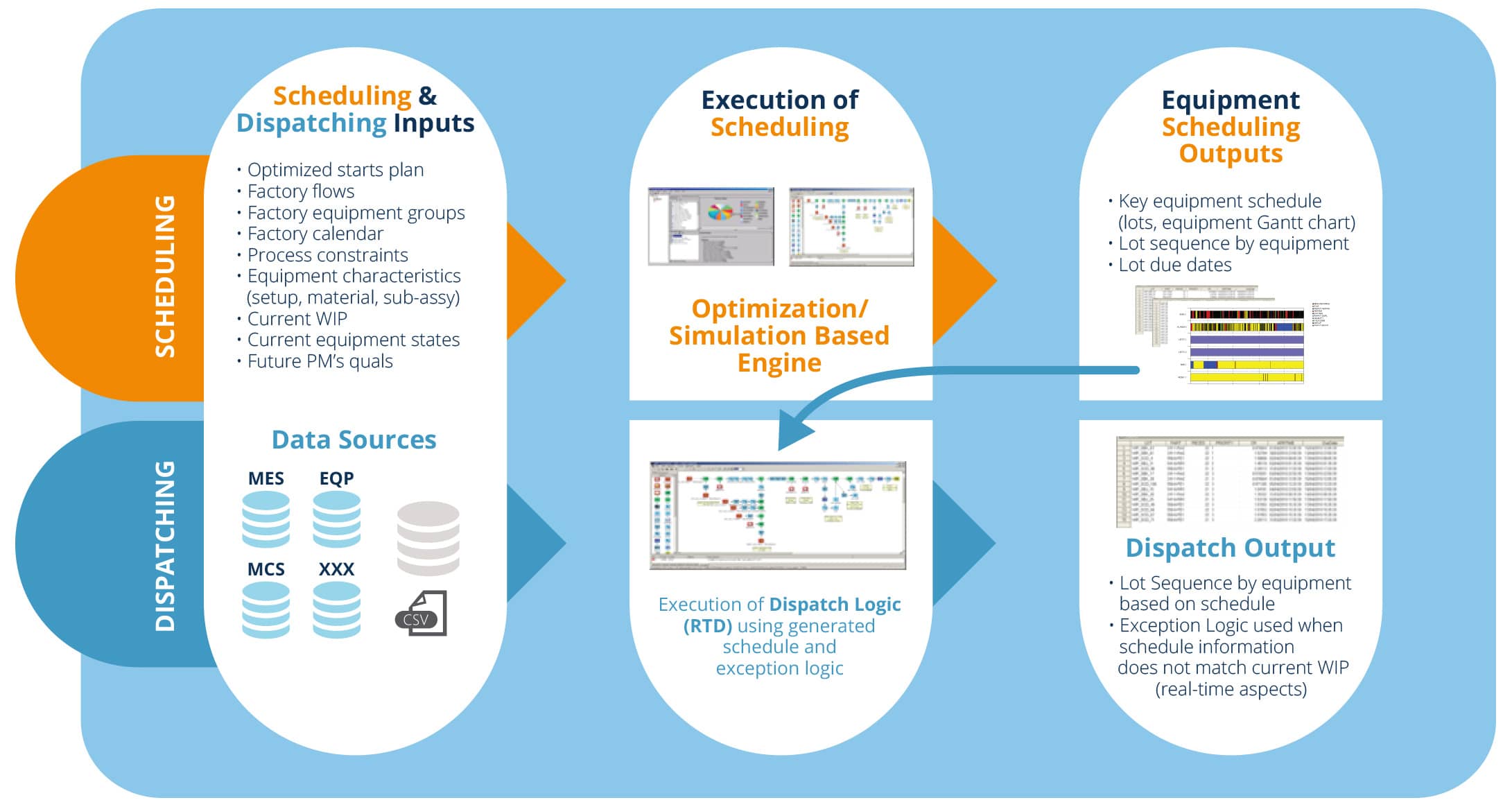

One more common misconception is that you only need a scheduling solution and not dispatching. Typically, schedules are generated every 5–15 minutes in a factory. During this time the factory floor encounters many changes. Equipment states might change, a lot might be put on hold or a process on qualified tools might become restricted. In their paper on near real-time scheduling and dispatching, Govind et al. present data on how often an area state changes1. Based on this data 50% of the changes occur in <5 minutes and 80% occur in <15 minutes. Due to this change a published schedule creates unclear and inconsistent decisions on the floor. Some of the challenges are:

- Manual Adjustments. An operator working from a 5 to 15-minute old schedule attempts to select a lot for the tool, but the lot is now on hold. The next lot on the screen is scheduled for a tool that just went down. In this case the operator must now adjust manually. This adjustment creates more idle equipment with WIP on hand, impacting throughput and cycle time.

- Schedule Responsiveness. Published schedules are unable to react in real-time for critical yield excursion recovery. In this case engineering needs to immediately restrict certain tools and funnel work to a golden tool “where possible.”

- Automated Transportation. In factories where transportation is automated using an overhead track (OHT) system or automated guided vehicles (AGVs) or other types or robots, they often fail to deliver lots to the correct equipment, resulting in numerous exception handling scenarios and creating white space on equipment.

Deploying an integrated scheduling and dispatching solution ensures that:

- Real-time adjustments to dynamic events in a factory occur with a consistent, heuristic-based approach.

- Rules incorporate both global and local parameters at a fast logic execution time (in seconds) for the lowest hanging fruit in productivity.

- Scheduling in highly constrained areas provide additional value when rules become too complex to provide an optimum path.

- Each domain is used to converge consistently and tightly with direct links toward factory objectives and key metrics.

Customers using our SmartFactory dispatching solutions improve throughput by 5-10% and increase productivity by another 3-5% by integrating these solutions.[1]

REFERENCE

[1] Operations Management in Automated Semiconductor Manufacturing with Integrated Targeting, Near Real-Time Scheduling, and Dispatching, Nirmal Govind, Eric W. Bullock, Linling He, Bala Iyer, Murali Krishna, and Charles S. Lockwood, IEEE TRANSACTIONS ON SEMICONDUCTOR MANUFACTURING, VOL. 21, NO. 3, AUGUST 2008