From reactive to prescriptive maintenance management

According to a NIST report1, preventable maintenance issues across U.S. discrete manufacturing (which includes semiconductor manufacturing) resulted in $119.1 billion in annual losses as of 2016. These losses stem from:

- Increased downtime

- Higher defect rates

- Lost sales due to delays and defects

- Inventory surpluses caused by maintenance inefficiencies

Smart manufacturing—often called “Industry 4.0”—is characterized by a shift from reactive and preventative maintenance approaches to more predictive and prescriptive operations, known as the “four ‘ives’ of smart manufacturing.” This shift is foundational, enabling factories to support all these capabilities at once. While some processes, like detecting component degradation, are moving toward predictive and prescriptive methods, others (such as random failure detection) remain reactive (Figure 1).

Maintenance represents an area of manufacturing where there is an opportunity to apply these advanced methods, because improvements can significantly boost factory throughput, quality, and cost efficiency. The application of smart manufacturing to maintenance is called Prognostics and Health Management (PHM), which connects failure mechanism studies to system lifecycle management. PHM encompasses equipment health monitoring (EHM), predictive maintenance (PdM), and maintenance assessment. These tools work together to reduce unscheduled downtime and improve uptime2.

Plug and play spares and ERP modules advantage

In a recent blog, we discussed the complexity in modern semiconductor fabs that rely on thousands of highly specialized tools. Each of these tools may contain tens of thousands of parts sourced from hundreds of suppliers. The problem they have is part availability and association. To maintain high Overall Equipment Effectiveness (OEE), fabs must ensure that the right spare parts are available at the right time. This requires tight coordination between physical systems (suppliers, warehouses, tools) and logical systems (ERP and maintenance management platforms). A key issue is associating part numbers (P/Ns) with maintenance work orders efficiently.

SmartFactory Maintenance Management addresses this challenge with two plug-and-play modules.

- Spares module: Links work orders to serialized and consumable parts, and tracks part consumption during preventive maintenance.

- ERP module: Enables fast integration with ERP systems using standardized data dictionaries and server-side rules. It supports (P/N) tracking, queries, and return flows.

The benefits this poses for semiconductor fabs include:

- Improved mean time to repair (MTTR): Faster maintenance due to better part-to-work-order association.

- Lower integration costs: Simplified ERP connectivity via standardized touchpoints.

- Enhanced data traceability: P/N usage and history are easily tracked.

- Reduced system complexity: P/Ns can move between systems without duplication.

- Boosted OEE: Outlier parts affecting Mean Time Between Failures (MTBF) can be identified and addressed.

Spares kitting advantage

Spare parts kitting in the semiconductor industry is the process of grouping all necessary components and tools for a specific maintenance or repair task into a single, pre-packaged kit. This method streamlines operations by ensuring that service engineers or production staff have all required items readily available, minimizing machine downtime and enhancing overall efficiency in the demanding cleanroom environment.

Among the key aspects and benefits of this process are:

- Minimized downtime: Technicians don’t spend valuable time locating individual parts in a warehouse because a complete kit can be quickly deployed when a need arises. A kit with all necessary parts is available through the ERP. This is done via simpler parts management—stores deliver one pre-packed kit rather than spending time searching for parts, bundling them, processing parts, etc. This saves time for both the technician and the warehouse worker (in ERP). This will also improve efficiency and productivity for engineers, as they can focus on high-value repair and assembly tasks rather than material handling and searching for parts. This accelerates production cycles and service response times.

- Enhanced inventory management: Each kit is managed under a single stock keeping unit (SKU), which simplifies inventory tracking and control. This makes demand forecasting easier and helps prevent overstocking or stockouts of individual, often expensive, components.

- Reduced errors and quality control: Pre-verified kits ensure that all the correct components, with full traceability and quality assurance, are available before a job starts. This minimizes the risk of using incorrect or defective parts, which is crucial in a high-precision industry like semiconductor manufacturing.

- Cost savings: Kitting reduces administrative overhead (fewer purchase orders are needed), lowers storage costs, and minimizes waste from obsolete or damaged parts.

- Optimized logistics: Kitting simplifies shipping and logistics by consolidating multiple items into a single package, reducing handling and transport costs. Kitting can be performed in-house or outsourced to a third-party logistics provider with expertise in handling sensitive electronic components and a network of strategic stocking locations to meet service level agreements.

By standardizing the parts needed for common repairs or maintenance schedules, semiconductor manufacturers can build a more resilient and efficient supply chain.

In recent release we enabled an enhancement to the spares module by improving kitting functionality to address the above.

There are several key benefits of SmartFactory Maintenance Management spares kits, including:

- Simplified ordering: A single request for a kit replaces multiple part orders.

- Streamlined logistics: Related components are grouped for easier transportation and tracking.

- Improved maintenance workflow: During maintenance, all parts in the kit are installed, and the removed parts are returned in the same container.

There are two types of spares kit, a process kit and a consumable kit. The process kit contains durable serialized parts and follows the serialized part state model and transitions. A consumable kit contains consumable non-serialized parts and follows the non-serialized part state model and transitions. A kit is considered a part, and all actions applicable to parts can also be performed on a kit. This can be done by creating a work order estimate in the work order parts section and executing relevant actions.

Use case example

In a high-volume 300mm semiconductor fab, a critical photolithography tool fails during peak production. The maintenance team scrambles to diagnose the issue and initiate a corrective work order. However, the required parts—scattered across multiple suppliers and storage locations—are not readily available. Some are serialized, others consumable, and a few are missing due to ERP mismatches. The result?

- 12+ hours of tool downtime

- Missed production targets

- Increased defect rates from rescheduling stress

- Excess inventory from over-ordering “just in case” parts

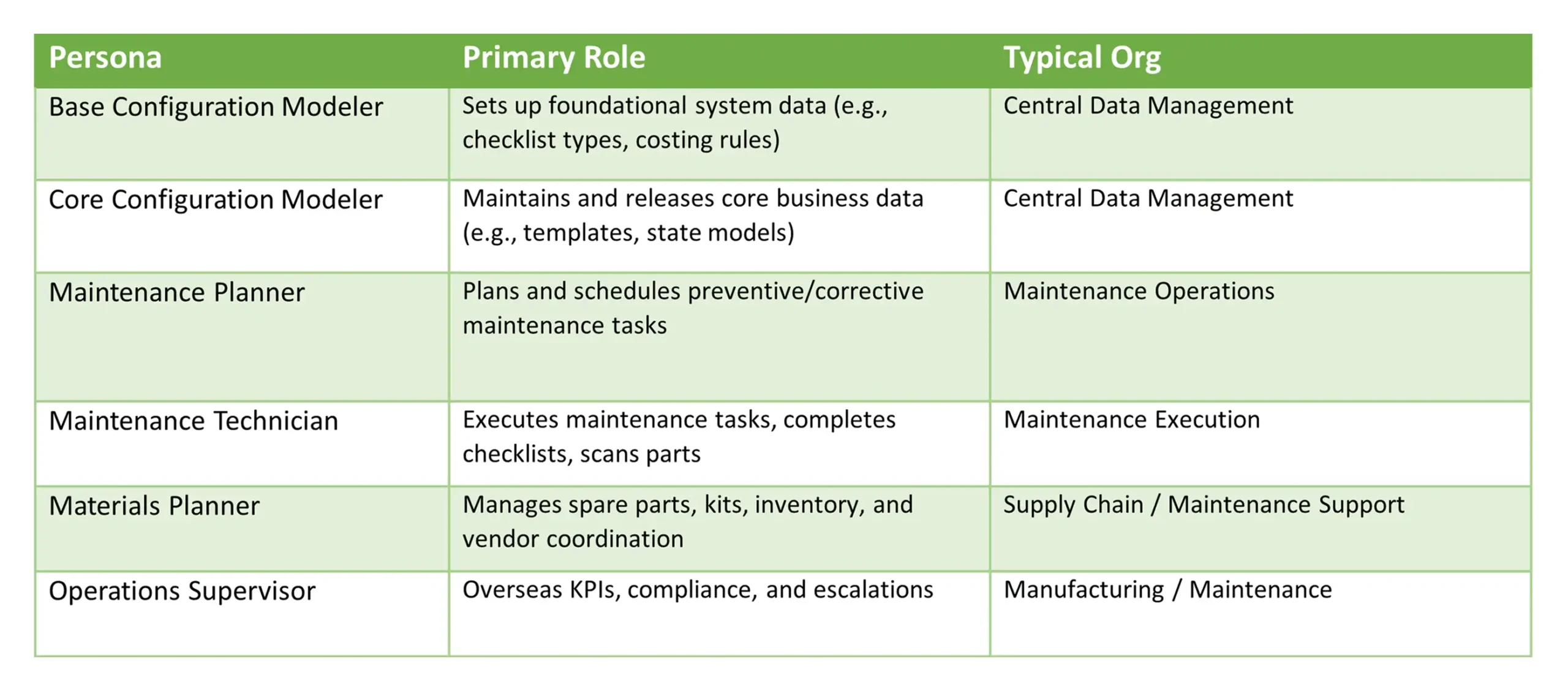

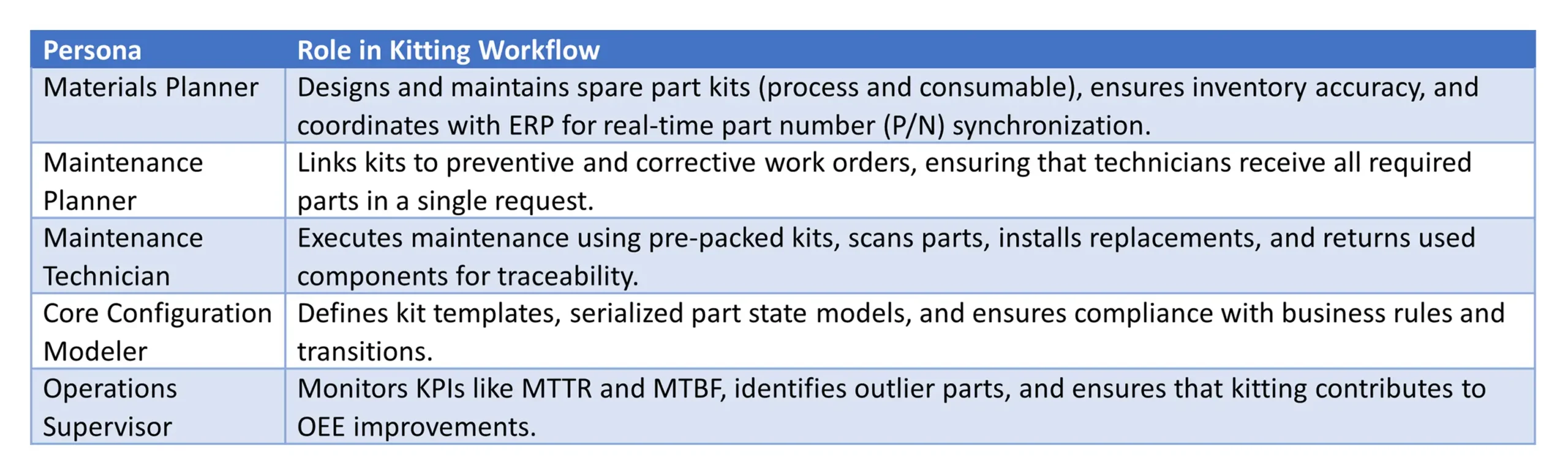

To address this, the fab implemented SmartFactory Maintenance Management Spares and ERP Modules, with a focus on spares kitting. Table 2 shows how each persona plays a critical role in making it work:

The impact: persona-driven efficiency

- The maintenance planner triggers a single kit request.

- The materials planner ensures the kit is stocked and delivered.

- The technician receives a pre-packed container with all required parts.

- Used parts are returned in the same container for traceability.

- The operations supervisor sees a 50% reduction in MTTR and improved OEE.

- Ripple effects on downstream tools

- Increased defect rates due to rescheduling

- Labor and recovery costs

Conclusion

Kits supported in Spares and ERP modules provide a structured approach to grouping related parts. This allows for efficient transportation, simplified ordering, and improved maintenance workflows. A kit serves as a physical container for parts meant to be replaced together during maintenance, reducing downtime and enhancing operational efficiency. It also simplifies procurement, transportation, and maintenance activities, ensuring that operations are more efficient and less prone to delays. If you’re ready to rethink how your fab handles maintenance, reach out.