Millions of Parts

The Right Part at the Right Time

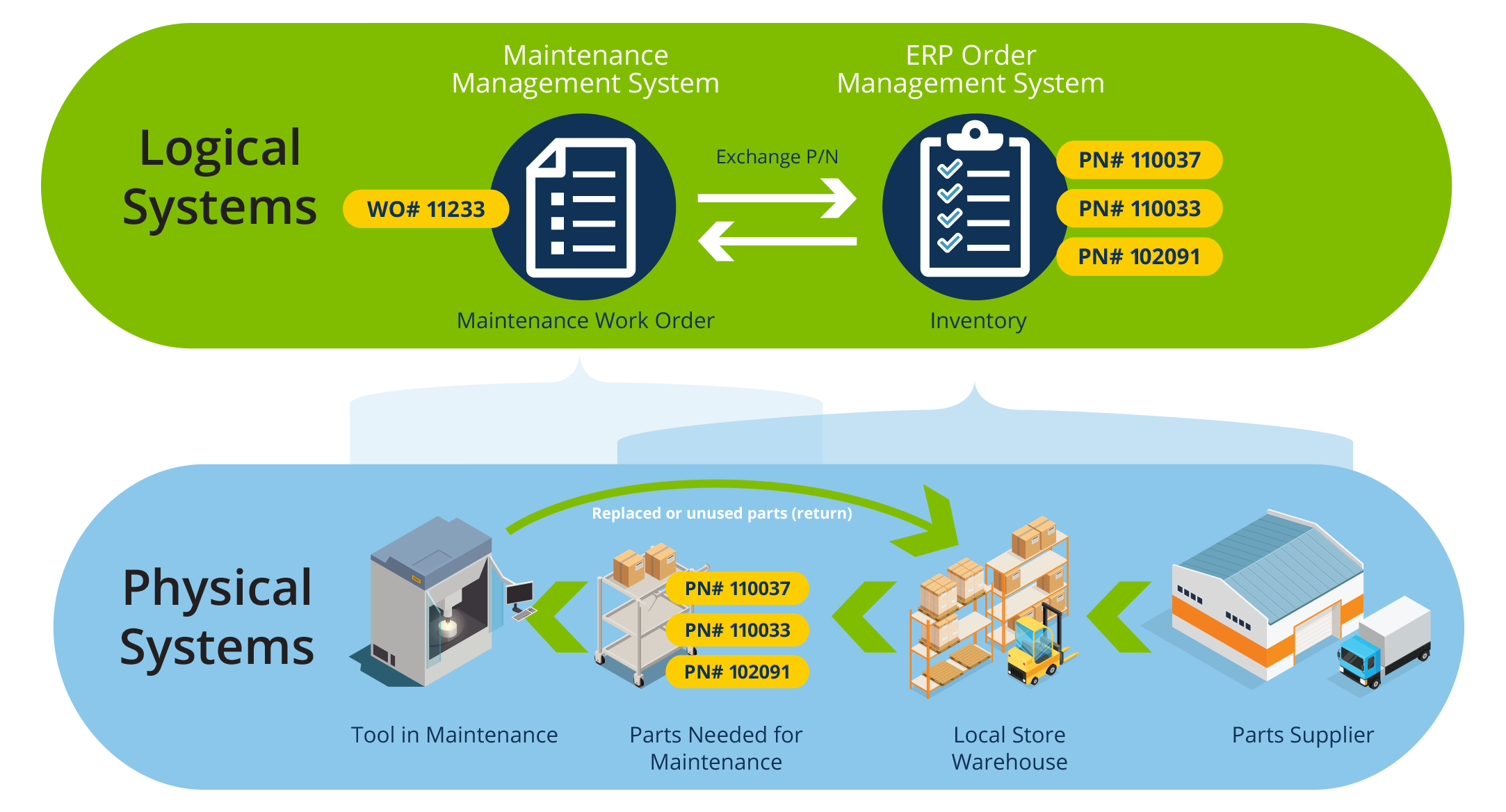

To manage this complexity, fabs must ensure parts availability. For all the thousands of tools and millions of spare parts, many of the most needed or replaced parts are available in-house, either within the fab or at a short distance nearby where parts are housed and ready for use in a local “Stores” warehouse. Other longer lead time parts are shipped and ordered as needed from OEM and 3rd party suppliers.

All this part complexity contributes to the OEE of an individual tool because parts and P/Ns must be associated with maintenance work done on the tool. When a maintenance work order is planned or triggered for a tool in a fab, the required spare parts must be available and associated with that work order. Given the risk of not having the right part at the right time for maintenance, a need exists to efficiently manage the association of P/Ns to maintenance work orders in a way that reduces complexity and ensures the right part at the right tool.The Exchange of Part Information

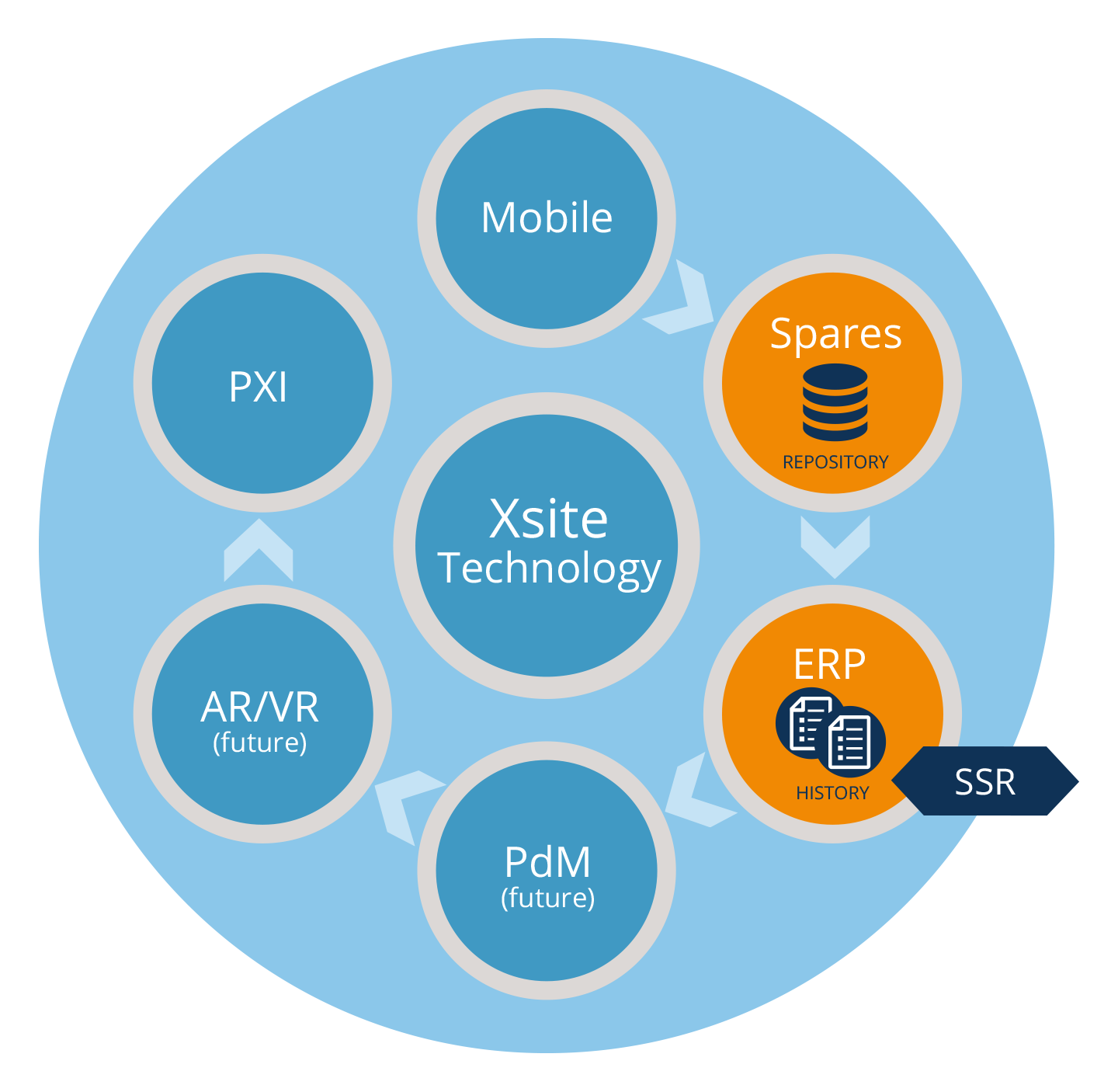

Applied Materials has a well-known maintenance management capability that is built on Xsite™ technology, which is used to efficiently automate maintenance schedules and track tool maintenance performance based on SEMI E10 states. This tracking ability provides a means of measuring OEE in terms of MTBF and MTTR metrics, which are captured automatically during maintenance when using the Xsite technology.

What Customers Have Told Us

- Automating and managing spare parts association to maintenance work orders

- Reduce system complexity by allowing the P/N to move between these two systems

- Providing faster-out-of-box integration with the ERP system

What Do These Modules Do?

- Associates work orders to P/Ns (both serialized and consumable parts)

- Consumes spares during PMs

- Standardizes the data dictionary and Server-Side Rules (SSRs) for fast out-of-box integration with ERP

- Allows P/N tracking history and queries

- Ensures P/N consumption and returns to ERP

What are the Benefits in a Semiconductor Fab?

Essential benefits of these modules for manufacturers include:

- Data traceability (P/N association and usage counts)

- Improved MTTR by providing the right part at the right time through P/N to work order association, which reduces maintenance down time

- Lower ERP integration cost by providing standard touch points and simple SSR configuration

- Reduced complexity — P/Ns move between systems and do not need to exist in both places

- Improved OEE—spares outliers can be identified because P/Ns can be queried and associated to out-of-bounds MTBF metrics