The SmartFactory Computer Integrated Manufacturing (CIM) solution allows manufacturers to define, control, automate, monitor, and record the entire semiconductor manufacturing process from front-end wafer fabrication through back-end assembly, test, and packaging. It does so through a portfolio of integrated software products that share information with each other via a common message bus that enables communication between CIM systems and applications.

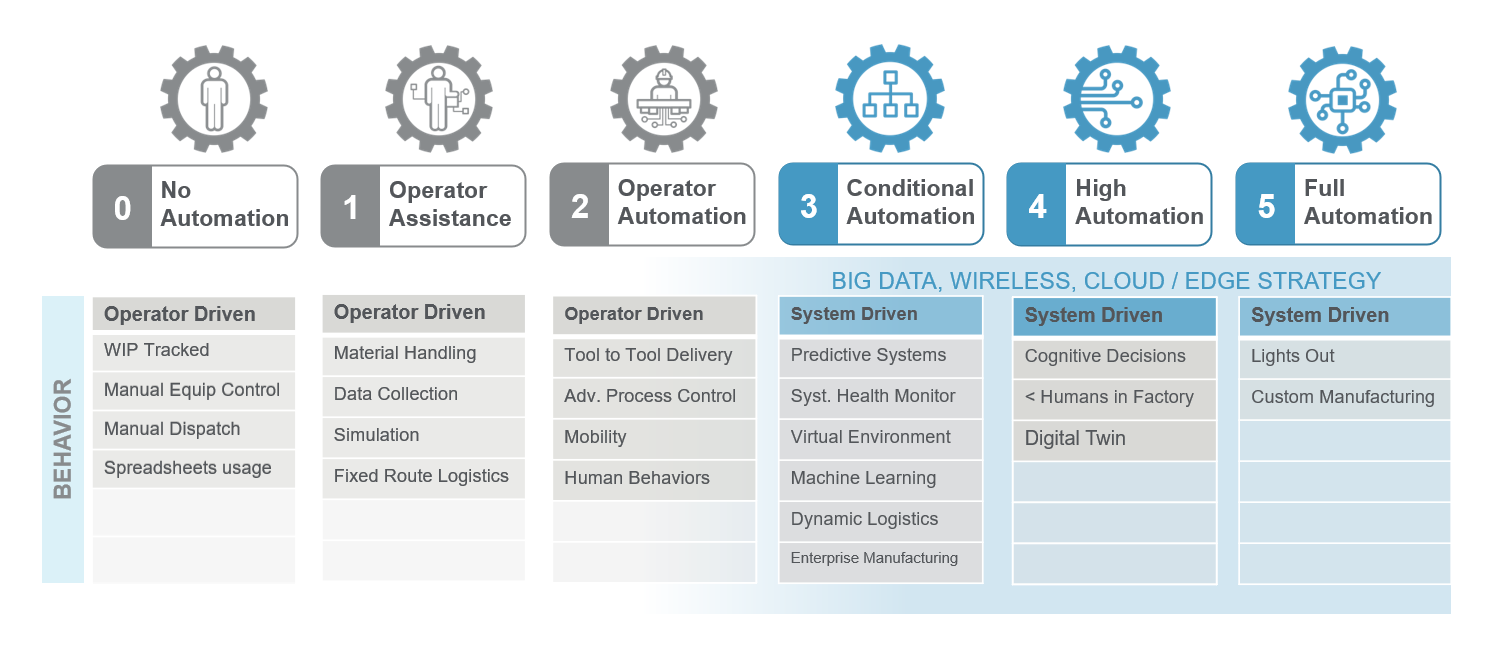

At the heart of the CIM is the Manufacturing Execution System (MES), which is the master coordinator of processing throughout manufacturing. The MES is the key integration point with all other CIM systems for product as it moves through manufacturing, and the message bus is central to that integration, enabling communication between systems and applications. As manufacturers have moved from a mix of manual control and low levels of automated manufacturing toward higher levels (see figure 1), greater demand has been placed on the message bus to do more, faster. The existing messaging bus is limited in that it doesn’t provide the features required to achieve the real-time decision making necessary to advance automation to its highest levels.

Next generation message bus

Pain Points

Scalability is also required to keep up with current market demands. There is so much data coming from each tool, every nanosecond, that there needs to be a very big pipeline for processing that data. The message bus needs to handle high message throughput, be scalable in the number of topics it can handle and accommodate rapid growth with low latency.

Customers also cite a need for multi-tenancy— low operating and maintenance costs, efficient use of resources and larger computing capacity. It’s also critical that a message bus operating at such a high level be durable, with guaranteed message delivery, zero data loss and failure recovery.

The other two pain points we sought to address were the need for geo-replication, the easy replication of message data between different regions and across different private or public clouds; and the need for a unified messaging and streaming platform for publishing and subscribing, storing and processing streams of data at scale and in real-time.

SmartFactory Message Bus Pulsar

In creating a next generation message bus solution, we leveraged Pulsar, an open-source software, and integrated it with our SmartFactory CIM through proprietary Pulsar adapters. We conducted a study two years ago comparing Pulsar to other similar types of message bus systems and Pulsar greatly outperformed the competition in the key areas we needed to address.

Our two-part solution of Pulsar and SmartFactory Message Bus Pulsar Adapter was designed with the capability to resolve customer pain points as well as meet future needs. It brings five major technological advances to our CIM messaging capabilities:

- Multi-Tenancy: Pulsar was designed for deployment as a hosted service for private and public cloud with multi-tenancy architecture.

- Scalability: Pulsar provides seamless scalability out to over a million topics with very low publish and end-to-end latency.

- Durability: Pulsar uses a modern architecture (brokers/bookies) for optimal performance and resiliency. It provides guaranteed message delivery with persistent message storage.

- Unified Messaging Model: Pulsar generalizes the two messaging concepts of queuing and publish-subscribe through one unified messaging API, enabling more use cases.

- Geo-replication: Pulsar offers geo-replication as a first-class feature, allows

organizations to deploy Pulsar across different cloud providers and replicate data across multi-cloud without locking in proprietary cloud provider APIs.