In our previous blog Alarm Management: from chaos to control, we outlined the challenges with mismanaged alarms in manufacturing. When mismanaged, they flood operators with noise and obscure critical issues, as well as contribute to costly downtime and scrap. One of these challenges is a silent productivity and yield killer in semiconductor manufacturing that often goes unnoticed: alarm fatigue. Alarm fatigue arises when operators are overwhelmed by frequent, often non-critical alerts from process control and other systems. This desensitization can lead to delayed responses or missed alarms, increasing the risk of equipment failure, yield loss, and safety incidents. Economically, alarm fatigue can result in significant downtime, reduced throughput, and higher operational costs due to inefficient troubleshooting and maintenance. Over time, these consequences can erode profitability and competitiveness, especially in high-volume, precision-driven fabs where even minor disruptions have outsized financial impacts. In this article, we will explore the economic burden of alarm fatigue and ways to resolve it using the best-in-class Alarm Management system.

Why does Alarm fatigue matter?

Alarm fatigue is a real problem across many segments. In the healthcare space for example, in intensive care units, patients may trigger more than 900 alarms per day, with 72–99% being false or non-actionable. This leads to clinicians ignoring alarms, resulting in missed critical alerts and patient harm, including delayed treatment and increased mortality. Alarm fatigue has been linked to serious patient safety incidents, prompting alarm management to become a National Patient Safety Goal since 2014.

An alarm fatigue example from pharma manufacturing is often associated with batch-level deviations and compliance risks. Excessive alarms in cleanroom environments or during sterile processing can lead to operator desensitization, risking product contamination or regulatory non-compliance. An example of a personalized medicine partnership between the Applied SmartFactory Rx team and Moderna to address major alert to action issues in pharma manufacturing can be found here.

In the oil and gas industry, a relevant example is a case faced by an oil producer, the Pipeline Monitoring (Emerson Zedi Case). Most of the alarms in this case were false, leading to ignoring real leak alarms, risking environmental damage and regulatory fines. AI-based alarm filtering reduced false positives and improved leak detection accuracy. There is also no shortage of examples in the chemical and process industries (Houda Briwa, 2022),1 where alarm flood resulting in operators’ fatigue caused severe injuries and fatalities, as well as major economic damage.

Alarm fatigue in semiconductor fabs, where a single deviation can trigger a cascade of alerts, is a growing problem. A study at STMicroelectronics2 found that more than 95% of alarms were low-priority and only 4% triggered any action. Even more striking, just 100 alarms out of 5,000 accounted for 70% of all alarm activity.

This flood of irrelevant alerts leads to:

- Delayed responses to critical issues.

- Missed alarms due to operator desensitization.

- Increased scrap rates and reduced yield.

- Higher maintenance costs and unplanned downtime.

Economic impact in semiconductor fabs

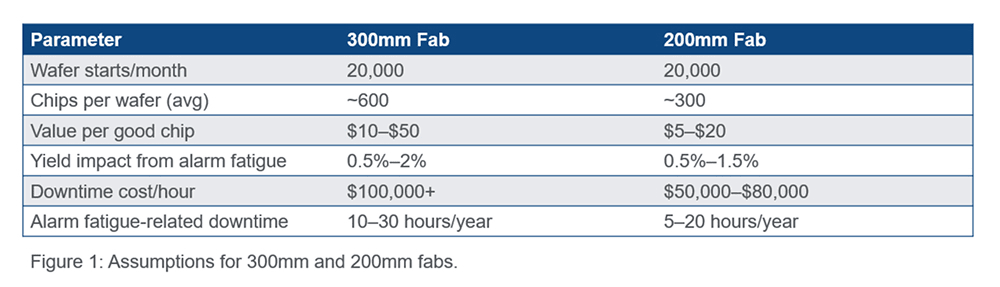

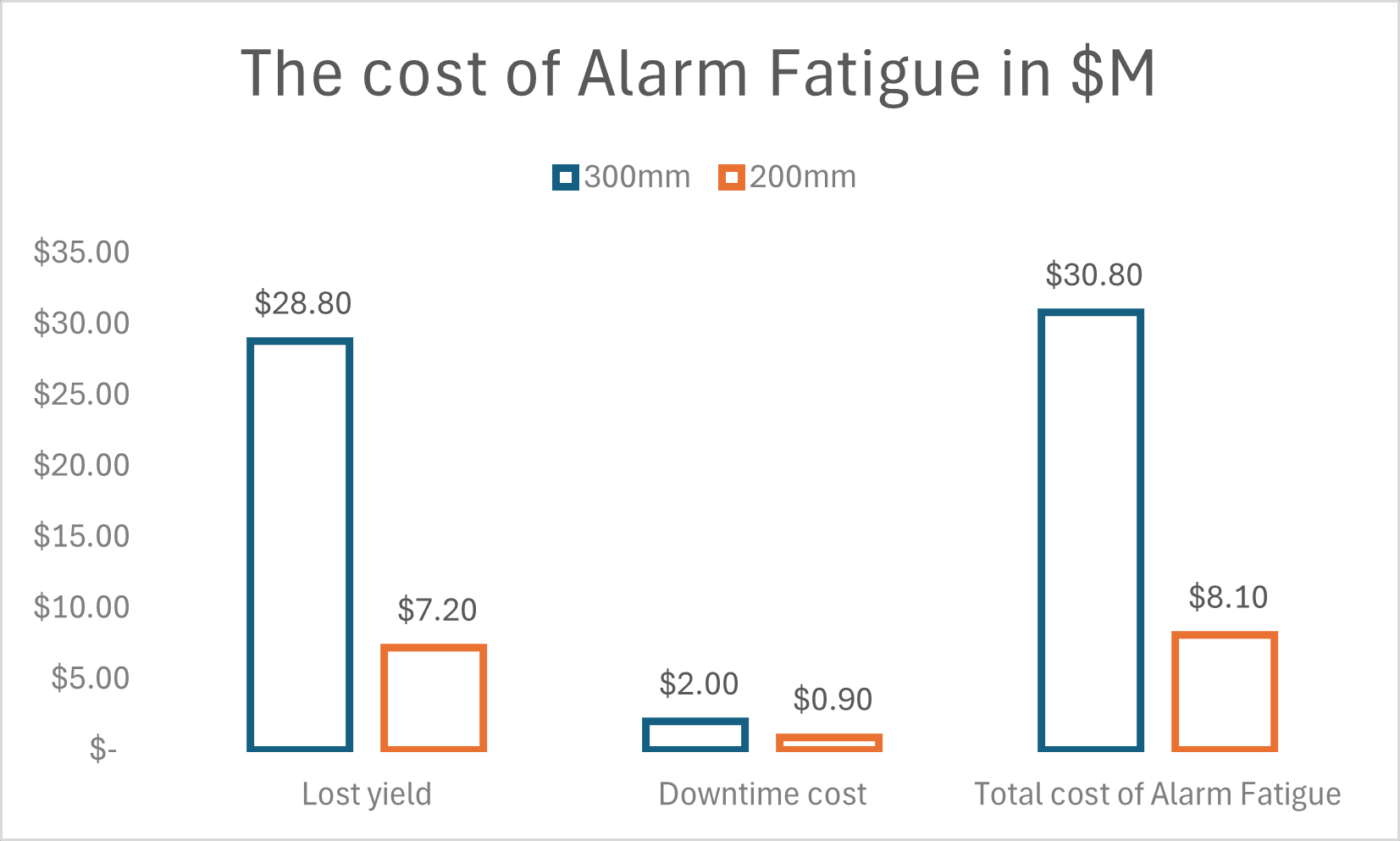

Based on these assumptions for 300mm fabs, the potential economic consequence of alarm fatigue, as shown in Figure 1, is:

- Lost yield: Up to $28.8M/year

- Downtime cost: ~$2M/year

- Total cost of alarm fatigue: ~$30M+ annually

For a 200mm fab with the same volume:

- Lost yield: ~$7.2M/year

- Downtime cost: ~$900K/year

- Total cost: ~$8M+ annually

The solution: SmartFactory Alarm Management

SmartFactory Alarm Management addresses these challenges by offering a centralized, automated, and integrated approach to alarm handling:

- Automated filtering and prioritization: Only meaningful alarms are forwarded, with duplicates and false alarms suppressed.

- Configurable notifications: Alerts are sent only to relevant staff, via email or SMS, with escalation paths if unacknowledged.

- Action automation: Alarms can trigger predefined actions like putting a lot on hold or logging a tool down across MES, equipment automation, and other systems.

- Comprehensive dashboarding: A real-time, factory-wide view of active alarms, plus historical analysis for root cause investigation.

- Integration: Integrated with other SmartFactory Computerized Integrated Manufacturing such as Manufacturing Execution System (MES), Equipment Automation (EA), Material Control System (MCS), Run-to-Run (R2R), Activity Manager (AMA), Fault Detection (FD), Recipe Management System (RMS), Knowledge Advisor (KA) etc.; this automatically triggers actions for faster response time.

The payoff: quality, efficiency, and peace of mind

By integrating alarm management into the broader SmartFactory ecosystem, manufacturers can:

- Reduce downtime by accelerating response to critical alarms and minimizing alarm fatigue.

- Improve yield by catching quality-impacting issues earlier.

- Empower operators with actionable, relevant alerts.

- Streamline compliance with ISA and EEMUA standards.

Conclusion

References

[1] Briwa Houda, 2022 – Alarm Management for huma performance. Are we getting better? Proceedings of the 32nd European Safety and Reliability Conference (ESREL 2022).

[2] Al-Kharaz et al., 2019 – Evaluation of Alarm System Performance and Management in Semiconductor Manufacturing. 6th International Conference on Control, Decision and Information Technologies (CoDIT’19).