In today’s semiconductor factories, it’s become increasingly difficult and time-consuming to generate valid data for factory productivity solutions.

To address this gap, Applied Materials is developing a common data model using the Extract, Transform and Map (ETL) capabilities modules from Applied’s APF (Advanced Productivity Platform) software environment.

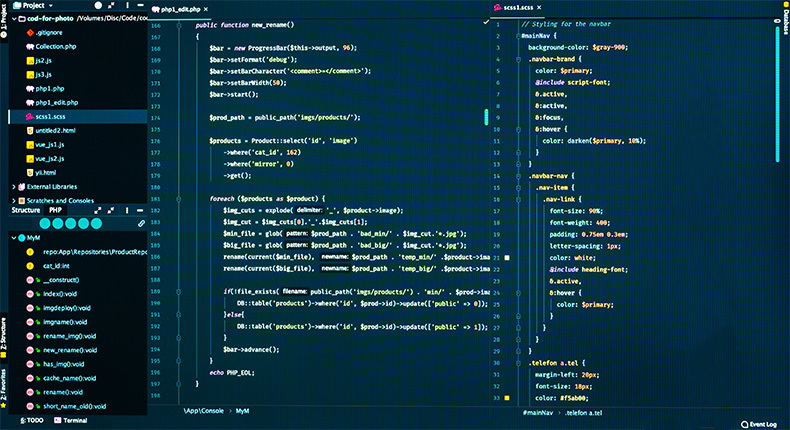

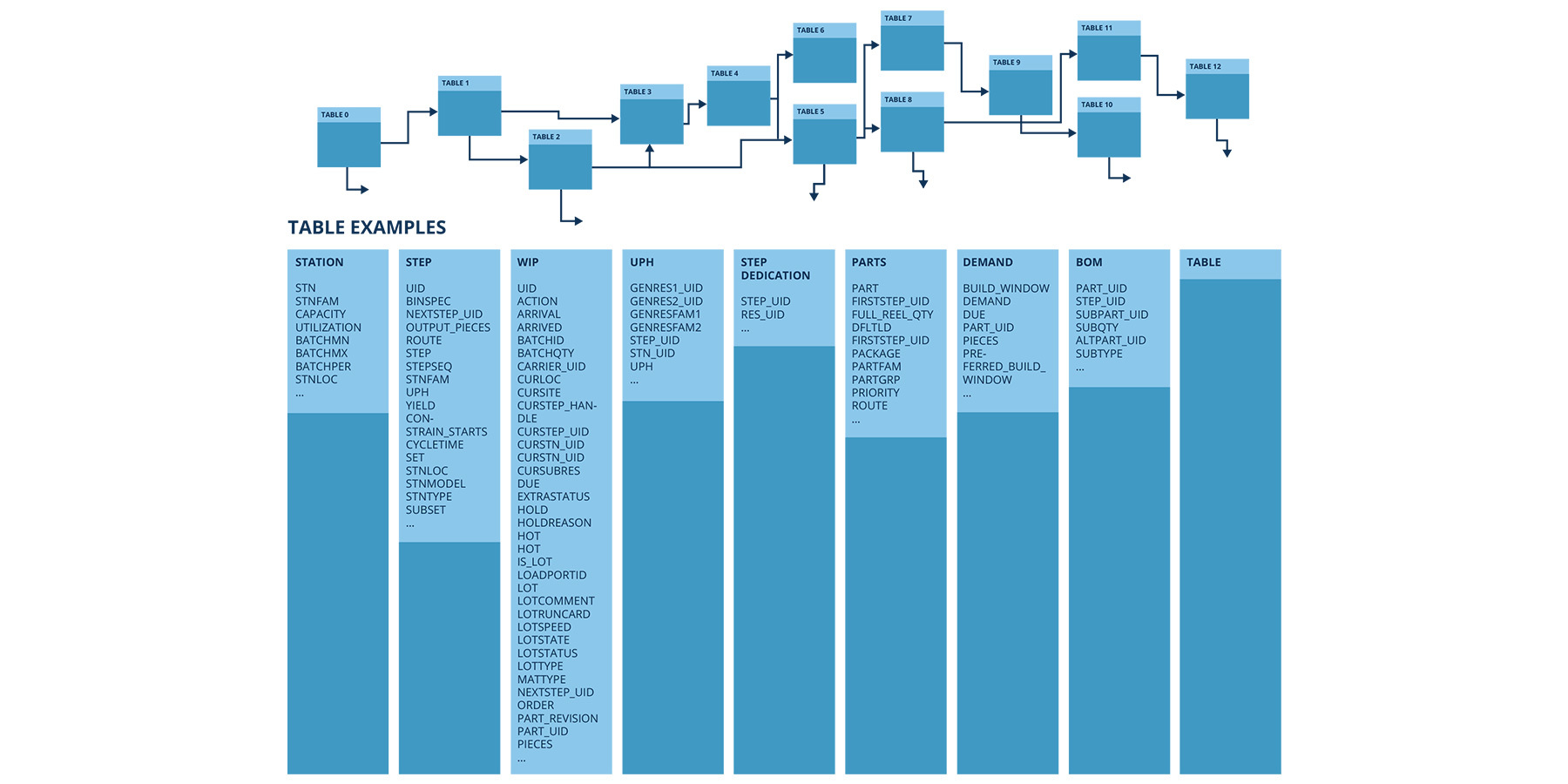

Figure 1 below shows steps involved in building the common data model schema

Smartfactory productivity solutions components

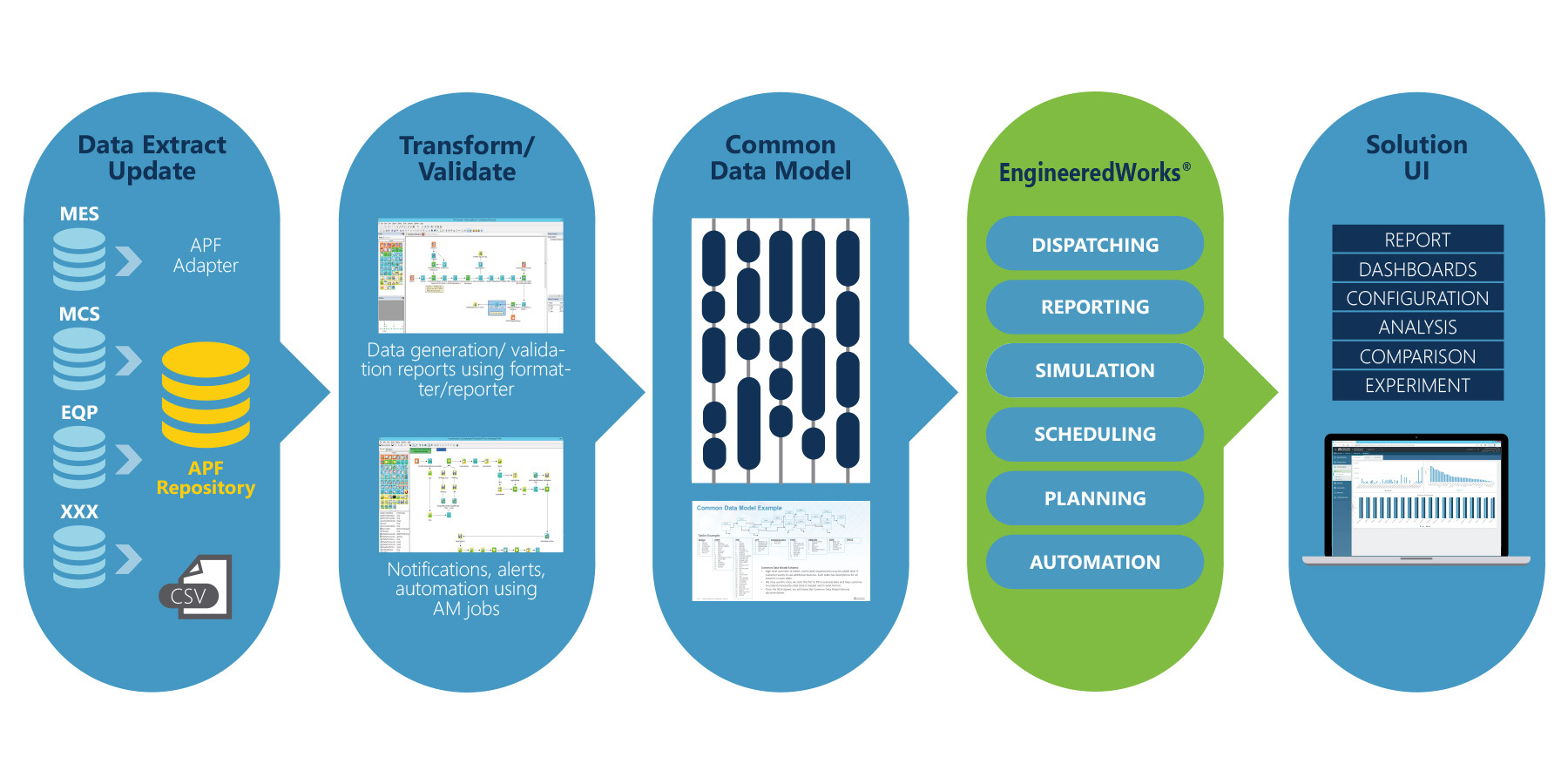

Applied solution leverages out of box APF adapters to integrate the data from various sources such as MES, MCS and other applications in the CIM solution.

Figure 2 shows the data intercepted from various solutions in APF repository

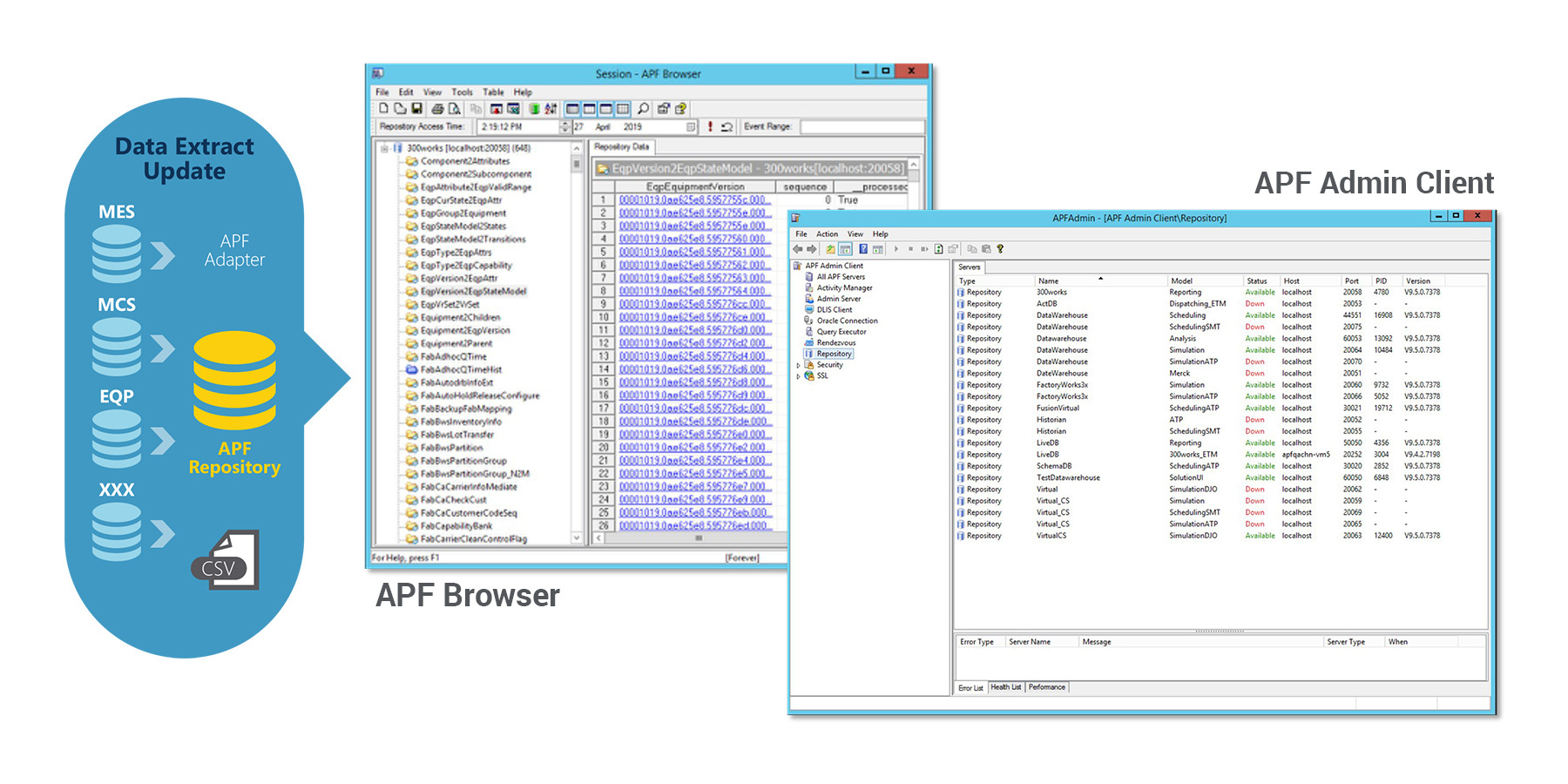

Extract, Transpose, and MAP(ETM)

Once the data is transformed in the common data model format then it is ready to get used in various factory productivity solutions.

Figure 4 shows some of the snapshot of various tables