Introduction to the consumables challenge

In our previous blog, we delved into the challenges and opportunities of durables management within semiconductor manufacturing, highlighting the pivotal role these mobile extension elements play in the manufacturing process. In this blog we turn our focus to consumables, which present us with a new set of challenges. Unlike durables, consumables are used up during production, necessitating a robust management system to track their lifecycle from procurement to disposal. The efficient handling of consumables like chemicals, gases, targets, etc., is crucial, as any misstep can lead to production delays, increased costs, and compromised product quality. In this follow-up discussion, we’ll unravel the complexities of consumables management and explore how innovative software solutions can address them.

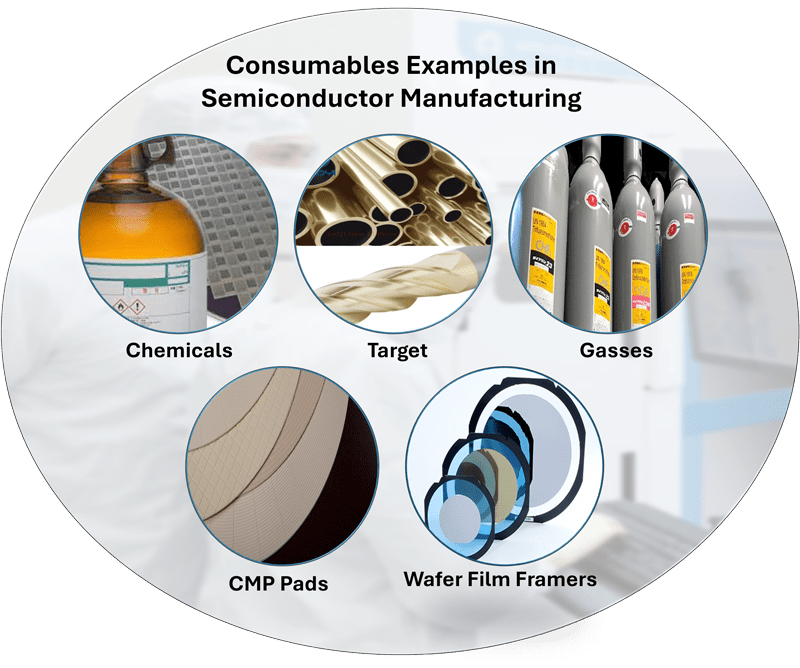

Examples of consumables used on the manufacturing floor include (see others in figure 1, below):

Clean Gas: Essential for maintaining a contaminant-free environment during manufacturing.

Wet Chemicals: Used for cleaning, etching, and stripping during the wafer fabrication process.

Developer: Used in photolithography to develop the image of the circuit onto the wafer.

Diffusion Materials: Include dopants that alter the electrical properties of the silicon wafer.

Etch Gas: Gases used for etching away unwanted materials to create the circuit patterns.

Fluid Dispense: Involves the distribution of various fluids used in the manufacturing process.

Photoresist: A light-sensitive material applied to the wafer surface to form the patterned coating.

CMP Pads: Critical for the chemical mechanical planarization process, ensuring wafer flatness.

Each of these has a specific role and is integral to the semiconductor manufacturing process. The next sections will delve deeper into consumables lifecycle, management systems, and the challenges faced in handling them.

The lifecycle of consumables

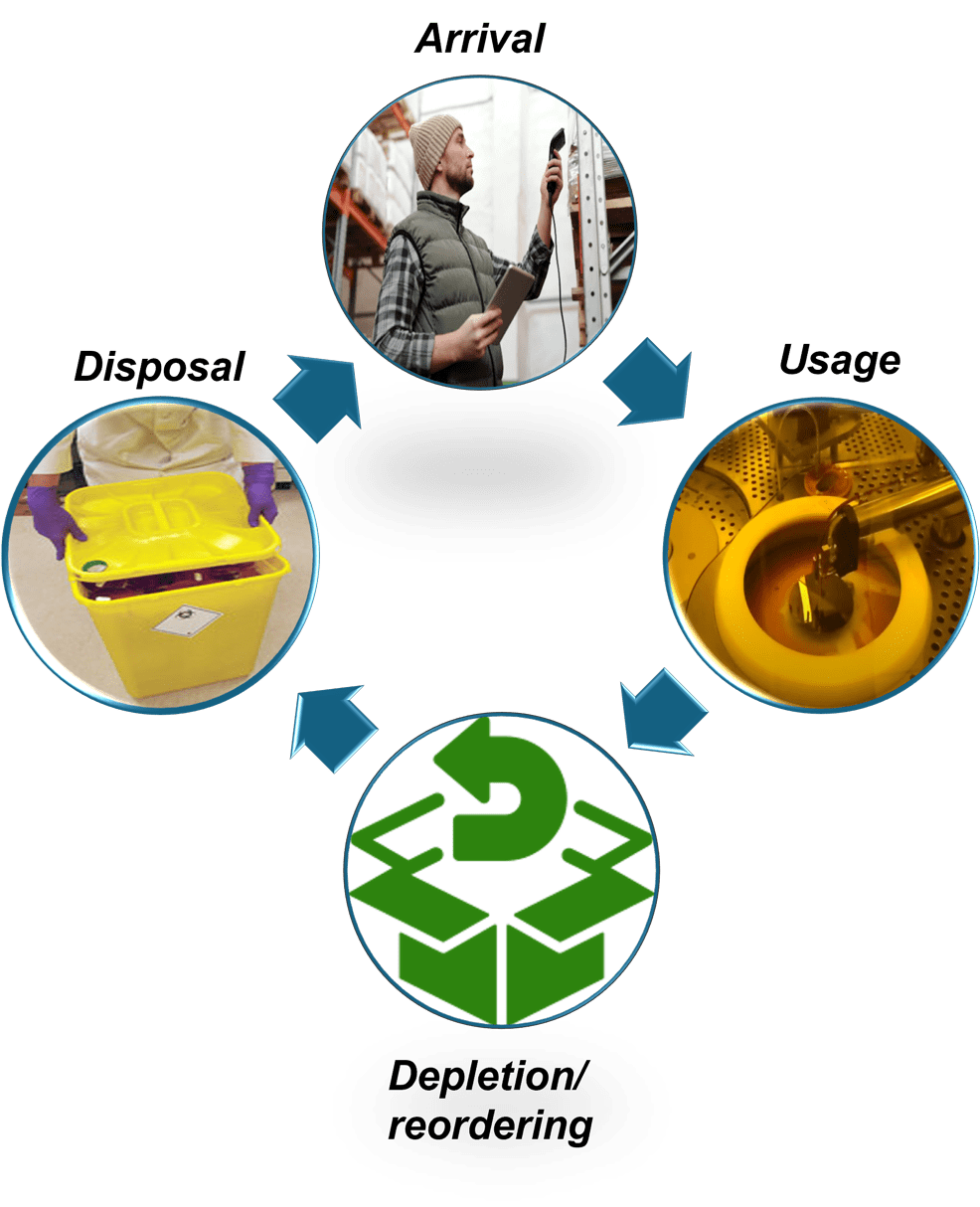

From its arrival on the manufacturer’s receiving dock, to the inventory room, the manufacturing floor and disposal/refill, each consumable’s journey needs to be carefully tracked and managed. Improperly managing consumables can be very costly and lead to a lot scrap and major delays supplying customer’s orders. Key life cycle steps of consumables are (as depicted in figure 2):

Arrival and storage: Upon arrival, consumables are logged into inventory systems with details such as expiration dates and storage conditions.

Usage: During production, consumables are used in various processes, often within tightly controlled environments to prevent contamination. For example, the consumable can be a heat sensitive chemical. This will highly impact the compatibility, quality, and shelf life of a consumable.

Depletion and reordering: As consumables are depleted, systems automatically flag low levels and assist in reordering to prevent production delays. Connecting these systems to suppliers allows constant replenishment of the consumables.

Disposal: Post-use, consumables are disposed of in accordance with environmental and safety regulations.

This cycle ensures that the right consumable is available at the right time and in the right condition, which is crucial for maintaining the high standards of semiconductor manufacturing.

Challenges in consumables management

Several challenges come to mind with consumables:

- Quality: Ensuring the quality of consumables is paramount, as subpar materials can lead to production defects and yield loss. In this case, supplier quality, ability to manage vendors and having clear audit trail capabilities are prudent. Furthermore, the ability to track consumables at the tool usage level and provide parametric context (i.e., SPC charts) could provide a major upside opportunity for process quality improvement.

- Inventory accuracy: Maintaining accurate inventory of ‘at spec’ consumables levels are critical.

- Cost control: Balancing the need for high-quality consumables with cost constraints.

A solution that can holistically address these challenges and integrate well with other systems is needed to ensure steady high-quality manufacturing.

Ideal consumables management systems

Effective management of consumables is facilitated by specialized software systems that integrate seamlessly with the broader manufacturing execution system (MES) and other systems such as Scheduling, SPC, etc. These systems should include:

- Real-time tracking: Monitoring the location and usage of consumables in real-time

- Inventory management: Automated inventory control, including alerts for low stock and expiration dates

- Usage analytics: Data analytics of where the consumable was, what it went through, lot and batch context, etc., are useful to optimize the use of consumables and reduce waste

- Compliance and reporting: Ensuring compliance with industry standards and generating reports for audits and quality control

By leveraging these systems, manufacturers can achieve a harmonious balance between operational efficiency and cost management.

Use cases examples

Photoresist chemicals

In the chip manufacturing process, the role of consumables such as photoresist, wet chemicals, and clean gases are critical. Let’s take the example of a semiconductor manufacturer facing challenges with their photoresist chemicals. These chemicals are sensitive to environmental conditions and have a limited shelf life, making their management complex.

Problem: The manufacturer experiences inconsistencies in their photolithography process, leading to defects in the circuit patterns.

An ideal solution: A software which provides the following benefits:

- Environmental control: The software integrates with the manufacturing floor on tool, storage, and in transit environmental systems to ensure optimal storage conditions for the photoresist chemicals.

- Inventory monitoring: Tracks the quantity and shelf life of photoresist chemicals in real-time, alerting the team before expiration date and/or stock reaches critical levels.

- Usage tracking: Monitors the usage patterns so the manufacturer can optimize their ordering schedule, reducing waste and costs.

- Quality assurance: The software records each consumables batch’s performance, allowing the manufacturer to trace defects back to specific chemical lots and address quality issues with suppliers.

Physical vapor deposition (PVD) process targets

In the PVD process, the target is a critical component, serving as the source material that gets vaporized and deposited onto a substrate to form a thin film. Targets can be made of various materials, including metals, alloys, and ceramics. Ensuring cleanliness and managing the erosion of the target can be challenging. Contaminants and uneven erosion can significantly impact the film’s quality and consistency.

Problem: There is no good system to track target usage, move it to refurbishment if need be and get it back. Another challenge is managing the transition based on parametric data from in-use to scrap. Additionally, there is no good system to disqualify a target based on its Certificate of Analysis (CofA) acceptance and send it back to the supplier (i.e., supplier quality).

An ideal solution: A software which provides the following benefits:

- Lifecycle management: The software integrates with the PVD tool, repair shop, storage and any other location to enable traceability and management of these state changes. The state model changes are based on counters, timers and measurements coming from various manufacturing systems and/or can be pre-configured in the system.

- Move from in-use to scrap: Offering maximal flexibility for tracking the usage based on vendor recommended shelf life, parametric conditions or an operator/engineer on the spot manual change decision.

- Supplier quality: The software can be configured to adhere to CofA metrics and disqualify with clear state transition such as send back to supplier if parametric requirements aren’t met.

With such a solution semiconductor manufacturers can improve their yield, reduce waste, and enhance their overall production efficiency.