In semiconductor front-end fabs as well as back-end assembly, test and packaging (ATP) facilities, efficient and flexible factory-floor production dispatching is vital to high productivity. Dispatching is the process of determining the next job that should be processed—ideally in real time—then assigning it to the right tool or station and ensuring it gets there at the right time and with minimum queue time.

Although building an effective dispatching system is vitally important, it’s equally important do so quickly to achieve critical factory productivity and time-to-market goals.

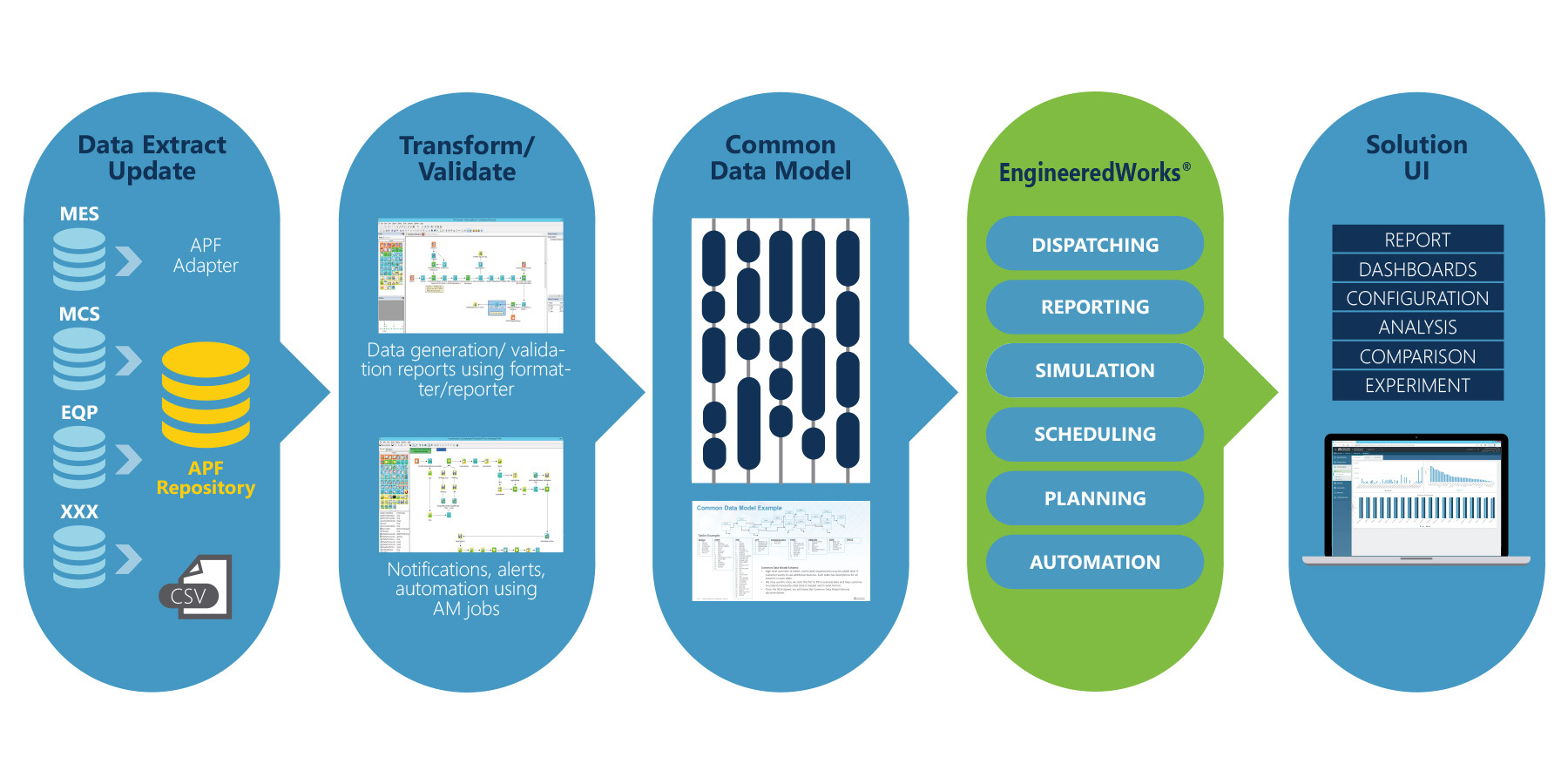

A way to accomplish these goals is to automate the dispatching process. Applied SmartFactory Dispatching & Reporting is an automated decision system that executes advanced rule-based, real-time dispatching, scheduling, and reporting strategies in both front-end and ATP factories. It is deployed with EngineeredWorks®, Applied’s prebuilt, out-of-the-box automation logic that executes on Applied’s proven APF platform and enables faster deployment times for dispatching systems (figure 1)

Case #1: Dispatching in a 150mm Fab

In 2015, one Applied Materials customer with multiple factories in Europe and Asia began to work with Applied to increase uptime utilization of key bottleneck tools at a European site.

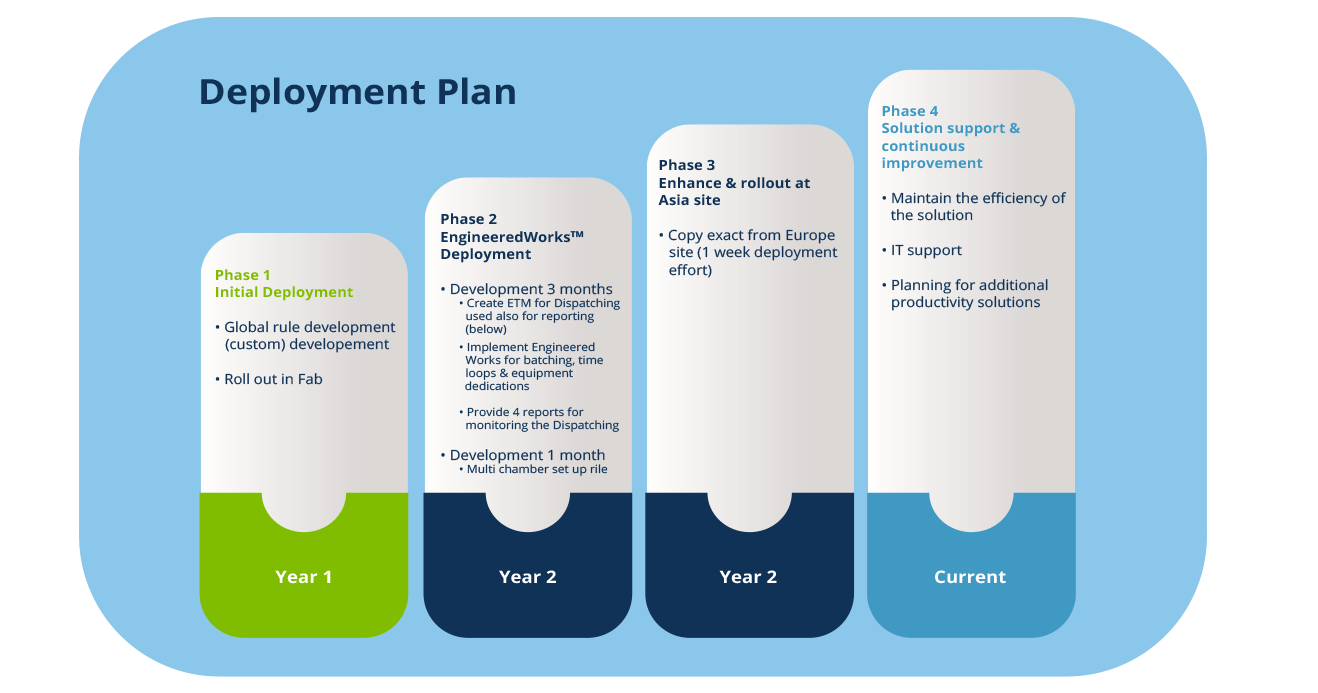

Initially, the customer decided to use a custom dispatching protocol. They purchased an APF license from Applied Materials and then took advantage of Applied’s services on a T&M (time and materials) basis to implement the global dispatching rule, which focused on line balancing to feed bottleneck tools better.

This initial implementation took one year. The development effort itself took about six months, and additional time was required to roll out dispatching rules in the fab as this was a big change for manufacturing personnel. Efforts were put in place to improve dispatching compliance and to gather input to improve the functionality of the dispatching rules.

However, the following year the company realized additional dispatching rules were needed for managing queue-time control and batching, while enhancements to the existing dispatching rules also were required. But with few resources dedicated to this project, and lacking the additional skilled resources needed for the deployment, the company looked for alternatives.

At this point Applied proposed the implementation of EngineeredWorks for dispatch, and the customer agreed. The project scope included developing an ETM (Extract Transform & Map) layer to map data from the factory’s MES system to a common data model, along with the development of additional dispatching rules and reports as shown in figure 2.

Using this approach, Applied and the customer were able to tailor EngineeredWorks for dispatch to meet site requirements in just three months.

During this year of roll-out and implementation, the customer also decided to use EngineeredWorks for dispatch for its site in Asia. Following its successful implementation in Europe, the same solution was deployed at the Asian site in just one week, marking a huge reduction in deployment time from the nearly two years it took for the initial full-custom implementation.

Case #2: Dispatching for Assembly, Test and Packaging Sites

These issues were relevant at one Applied Materials ATP customer with multiple sites in the U.S. and Asia. Management selected Applied’s EngineeredWorks for dispatch for deployment at all their sites as a first step towards full automation. The project was also expected to improve factory utilization by at least 8%. The first step in implementing these capabilities was to automate the dispatching decisions. EngineeredWorks for dispatch not only does this, it also provides pre-built interfaces to MES, scheduling and material control system (MCS) software (for controlling the AGV devices).

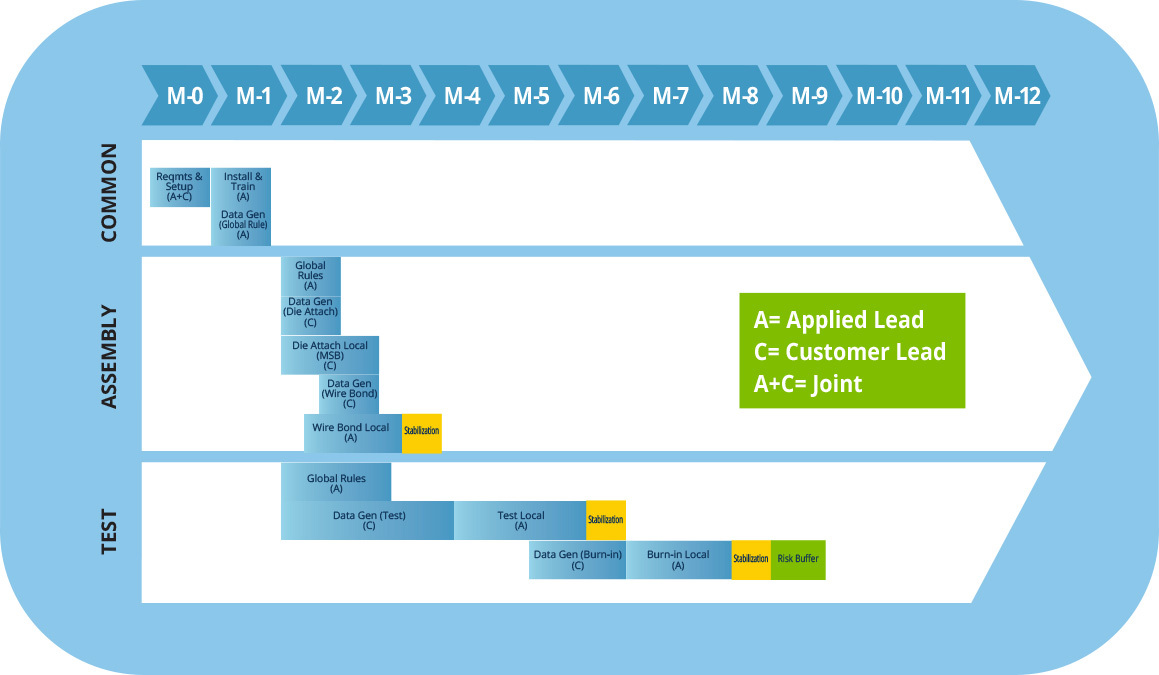

The initial project was to deploy EngineeredWorks for dispatch at 4 sites within 8 months, The project plan for this implementation is shown in figure 4.

Applied and the customer developed a collaborative project plan in which Applied took the lead in development and customization of EngineeredWorks based on the customer’s requirements, while the customer was responsible for mapping its data into the common data model. Applied and the customer had joint responsibility for the roll-out, which enabled them to quickly address any issues that arose.

All development work and the initial deployment was done at one lead site, and after a successful implementation there, EngineeredWorks for dispatch was rolled out to 3 other sites in parallel. Although this was challenging because the 4 sites were at different geographical locations, Applied was able to provide local deployment resources at each site in addition to expert resources at the lead site for development and integration.

The initial deployment was scheduled to be completed in a couple of months, but it took longer because of data availability and accuracy issues. Nonetheless, with close collaboration between both teams, the issues were resolved and EngineeredWorks for dispatch was successfully deployed as initially planned at four sites within 8 months.

In addition, the initial results post-deployment showed that the sites also achieved tool utilization improvements of more than 8%. The customer is now looking at implementing automated guided vehicle transport solutions.